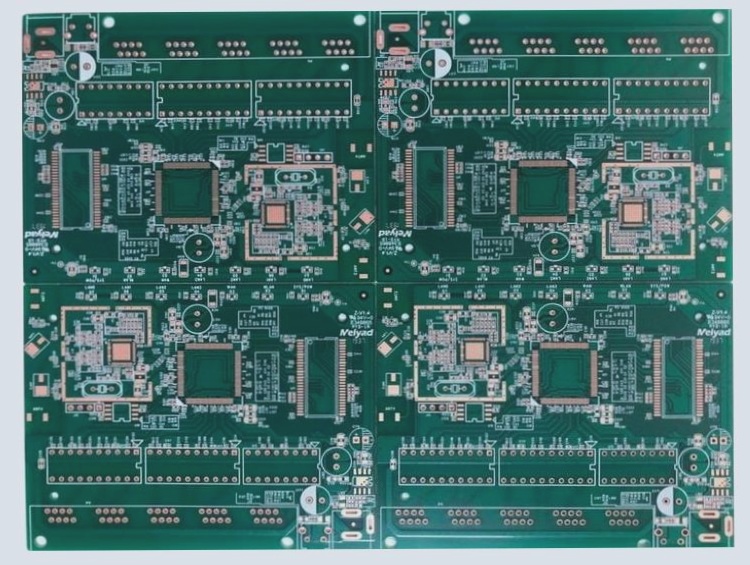

1. In the PCBA processing and copying process in Shenzhen, PCB scanning is undoubtedly the first step of all procedures.

2. Therefore, we must first obtain a quality PCB board, which should then be scanned by the computer as needed, followed by backing up the relevant parameters and the original PCB layout.

3. After disassembling the board, we acquire the split PCB light board, officially entering the copying stage, where our first task is scanning.

4. Initially, we need to store and record the PCB image.

5. It’s important to note that to ensure the relevant parameters on the PCB are clearly visible post-scanning, we must first remove any stains and residual solder from the PCB surface.

6. Here, we introduce the concept of DPI, which refers to the number of dots per inch.

7. Specifically, the distance between every two points on the scanned image is 1000/DPI, with the unit being mil.

8. Therefore, when copying a mobile phone board, the DPI is set to 1000 for scanning, resulting in a distance of 1000/1000=1 mil between two points, indicating an accuracy of 1 mil.

9. One crucial point in Shenzhen’s PCBA processing is that higher accuracy in the scanned image results in a larger file size and increased hardware requirements.

10. Thus, we need to set the DPI based on the specific conditions of the original board to ensure optimal results in the subsequent copy board process.

11. WellCircuits is pleased to be your business partner.

12. Our goal is to become the most professional prototyping PCB manufacturer globally.

13. With over ten years of experience in this field, we are dedicated to meeting the diverse needs of customers from various industries in terms of quality, delivery, cost-effectiveness, and other demanding requirements.

14. As one of the most experienced PCB manufacturers and SMT assemblers in China, we are proud to be your best business partner and a reliable ally for all your PCB needs.

15. We strive to make your research and development work seamless and worry-free.