Factors Affecting PCB Prices

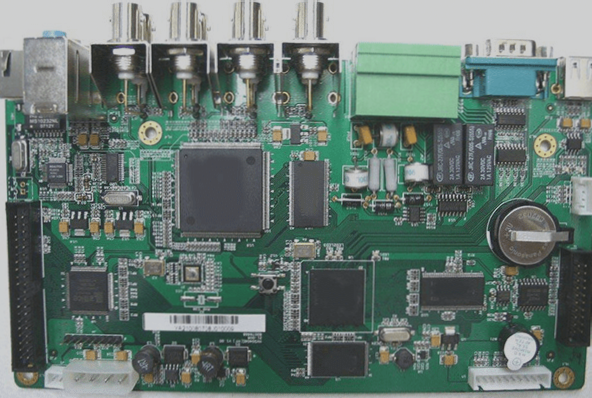

- Materials: The choice of materials, such as FR-4 or CEM-3, thickness options, and copper thickness, along with the type of solder mask ink used, can impact PCB prices.

- Production Processes: Different processes like gold-plating, tin-spraying, milling, punching, silk-printed circuits, or dry film circuits result in varying costs.

- Complexity: The complexity of the PCB circuit board, including factors like the number and size of holes, line widths, and line spacings, can lead to differences in pricing.

- Customer Requirements: Customer specifications, such as meeting IPC-A-600E class 1 or class 3 standards, can affect pricing based on the yield of the board factory.

- Manufacturer Variances: Different manufacturers with varying equipment and technical capabilities may offer different prices for the same product.

- Payment Methods: Prices may be adjusted based on payment terms provided, with discounts typically ranging from 5% to 10%.

- Regional Variances: Regional differences, such as price variations from south to north in China, can impact PCB prices across different regions.

Latest Information:

Recent trends in the PCB industry show a growing emphasis on eco-friendly materials and processes. Many manufacturers are now offering PCBs made from recycled materials and utilizing energy-efficient production methods to reduce environmental impact. Additionally, advancements in technology have led to the development of flexible and rigid-flex PCBs, catering to the increasing demand for compact and lightweight electronic devices.