The Factors Affecting PCB Prices

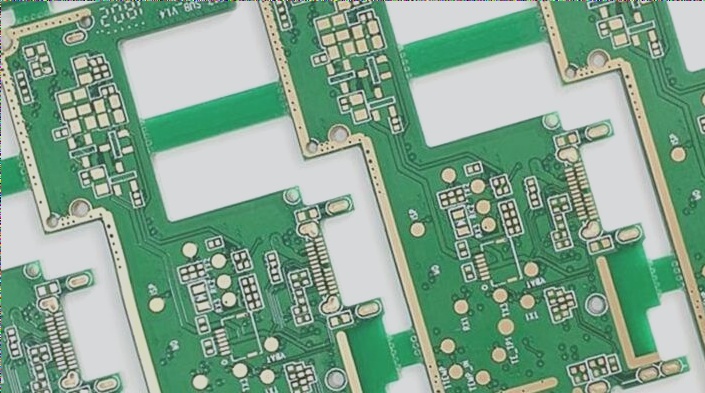

- The choice of materials: Different materials like FR-4 or CEM-3, varying thickness options, and copper thickness can impact prices.

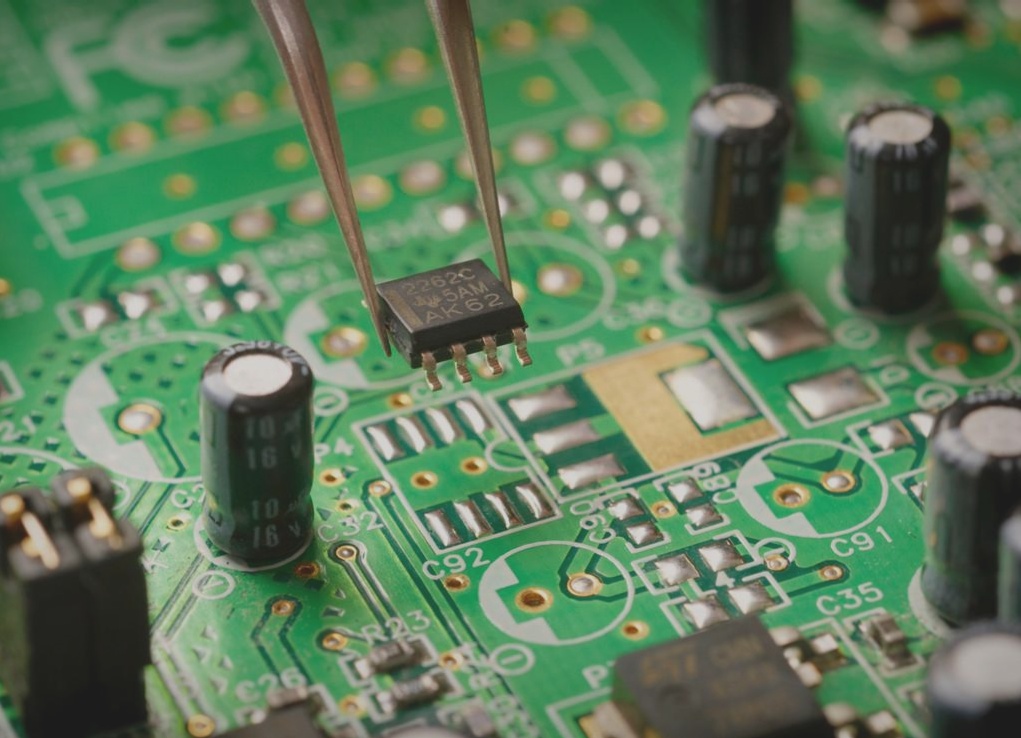

- Production processes: Gold-plating, tin-spraying, milling, punching, silk-printed circuits, and dry film circuits all contribute to cost differences.

- Complexity of the PCB: The number of holes, hole diameters, line widths, and line spacings affect production costs.

- Customer requirements: Boards meeting different IPC specifications can lead to varying prices based on pass rates.

- Manufacturer differences: Variances in equipment, technical capabilities, and preferred processes can result in price discrepancies.

- Payment methods: Prices may be adjusted based on the payment terms provided by PCB manufacturers.

- Regional disparities: Prices can vary across regions, with differences observed from south to north in China.

Recent developments in the PCB industry have seen a growing emphasis on sustainable manufacturing practices. Many PCB manufacturers are now investing in eco-friendly materials and processes to reduce their environmental impact. This shift towards sustainability not only benefits the environment but also aligns with the increasing consumer demand for greener technology products.

Furthermore, advancements in automation technologies have revolutionized PCB production, leading to increased efficiency and precision. Automated assembly lines and robotic soldering systems have significantly improved production speeds and product quality, ultimately driving down manufacturing costs and enhancing overall competitiveness in the market.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย