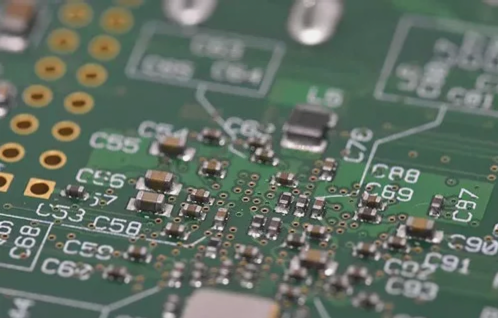

PCB Coating: Enhancing Protection and Performance

PCB coating is essential for safeguarding printed circuit boards (PCBs) from environmental factors and enhancing their stability and reliability. Various application methods, such as dip coating, spray coating, and brush coating, offer diverse options for maximizing protective effects.

Continuous Innovation in PCB Coating Technology

The field of PCB coating technology is constantly evolving, with the introduction of new materials that boast improved performance and environmental sustainability. Additionally, novel application methods are under exploration, highlighting the need for PCB experts to stay informed about the latest developments in the industry.

Importance of Quality Control

Quality control is paramount in PCB coating processes, encompassing materials, environment, and overall procedures. Strict adherence to quality control measures ensures that the coating meets performance standards, contributing to the stability and reliability of electronic equipment.

Wide Applications and Future Prospects

PCB coating finds extensive applications across industries such as communication, aerospace, and automotive sectors. As technology progresses, we anticipate further advancements and innovations in PCB coating, bolstering support for the continual growth of the electronics industry.

- Selecting appropriate coating materials and methods is crucial for maximizing PCB protection.

- Staying updated on the latest developments in PCB coating technology is essential for PCB experts.

- Rigorous quality control is necessary to ensure coating performance meets requirements.

- PCB coating plays a vital role in enhancing PCB performance and reliability across various industries.