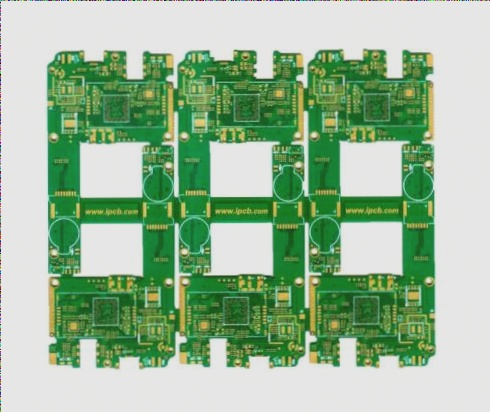

Understanding PCB Welding Quality

Welding plays a crucial role in the production of printed circuit boards (PCBs). PCBs act as a foundation for electronic components in various devices, facilitating vital electrical connections. As electronic technology advances, PCBs are becoming more intricate with increased layer counts. Despite having flawless designs, welding issues can result in defects, compromising the overall quality of the PCB. This can lead to a decrease in the pass rate of the circuit board and impact the reliability of the final product. Therefore, it is essential to identify the factors affecting PCB welding quality, address welding defects’ root causes, and improve overall welding standards.

Common Causes of Welding Defects

When it comes to welding PCBs, various factors can contribute to welding defects. By understanding these factors, manufacturers can take proactive measures to enhance welding quality and minimize defects. Some common reasons for welding defects include:

- Poor soldering techniques

- Inadequate heat control

- Improper component placement

- Contaminants on the PCB surface

- Incorrect solder alloy composition

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย