Comparing Plastics and Metals for CNC Machining

Advantages of Plastics

- Efficient Machining: Plastics allow for faster machining speeds due to their lower hardness, reducing tool wear and extending tool lifespan.

- Lightweight Design: With lower density, plastic parts are lightweight, making them ideal for weight-sensitive applications.

- Chemical Resistance: Plastics offer good corrosion resistance, suitable for specialized environments with chemical exposure concerns.

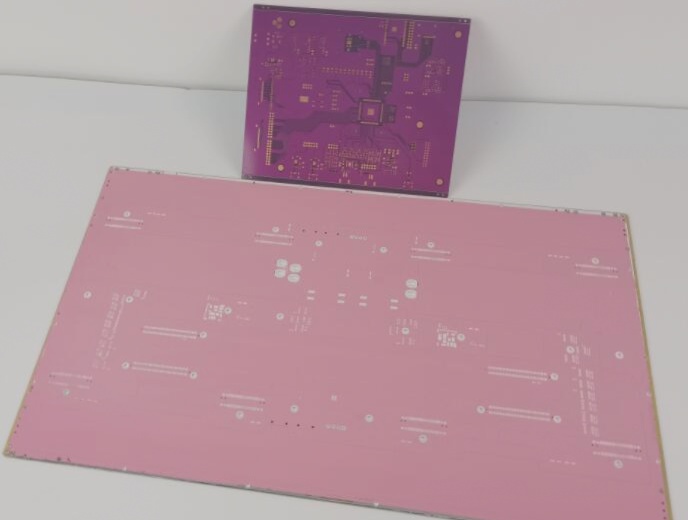

- Electrical Insulation: Plastics provide excellent electrical insulation, making them perfect for manufacturing electronic components.

Disadvantages of Plastics

- Low Strength: Plastics have lower strength and hardness, limiting their use in high-load applications.

- Thermal Expansion: High thermal expansion in plastics can cause dimensional changes and deformation with temperature fluctuations.

- Surface Quality: Plastic materials are prone to surface scratches and burrs during machining, requiring extra post-processing steps.

- Temperature Sensitivity: Plastics have poor temperature resistance compared to metals, leading to deformation in high heat conditions.

Advantages and Disadvantages of Metals

Advantages of Metals

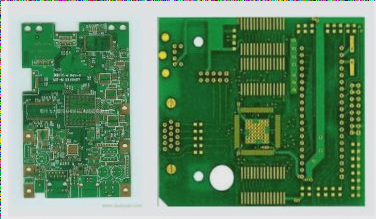

- Strength and Hardness: Metals offer superior strength and hardness, ideal for high-load applications.

- Dimensional Stability: Metals have low thermal expansion and excellent dimensional stability, suitable for high-precision tasks.

- Surface Finish: Metals can achieve a smooth surface finish, reducing the need for additional post-machining treatments.

- High-Temperature Resistance: Metals can withstand high temperatures, making them suitable for extreme heat environments.

- Mechanical Properties: Metal materials provide diverse mechanical properties that can be customized to meet specific application requirements.

Disadvantages of Metals

- Difficult Machining: Metals are challenging to machine due to their high hardness, requiring more machining power and harder tools.

- Tool Wear: Metals cause increased wear on cutting tools, leading to more frequent replacements and maintenance.

- Higher Costs: Metals, especially specialized alloys, are generally more expensive than plastics, contributing to higher production costs.

- Heavy Weight: Metals have higher density, resulting in heavier components that may not be suitable for lightweight applications.

- Corrosion Susceptibility: Many metals are prone to corrosion, necessitating additional treatments for enhanced durability.