Properties and Uses of Copper and Nickel Coatings on PCB Boards

-

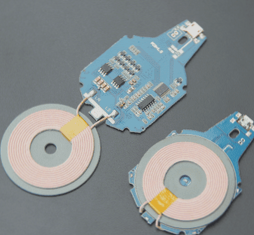

Copper Coating on PCB Boards

The copper coating on PCB boards is rosy, soft, and ductile, with excellent thermal and electrical conductivity. However, it easily oxidizes in the air, losing its luster. Copper coatings serve as foundational layers for multi-layer coatings and enhance adhesion between base metals and subsequent coatings like tin, gold, and silver. Thick copper and thin nickel plating processes improve corrosion resistance.

-

Nickel Coating on PCB Boards

Nickel coatings exhibit strong passivation capabilities, resisting corrosion and maintaining stability in the air. They offer exceptional polishing properties, hardness, and wear resistance. Nickel coatings are commonly used as base, intermediate, and surface layers for protective-decorative purposes. However, high porosity limits nickel’s application as a general protective coating.

-

Copper Plating Process for PCB Circuit Boards

Electroless copper plating, known as PTH (Plated Through Hole), involves an autocatalytic oxidation-reduction reaction. This process is widely used in PCB manufacturing, especially for metallizing holes. The hole metallization process includes drilling, deburring, cleaning, surface roughening, activation, copper immersion, and final rinsing.

The production scale of nickel coatings on PCB boards is substantial, accounting for approximately 10% of global nickel production.