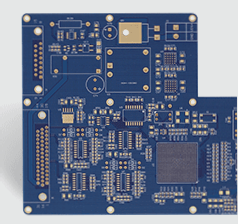

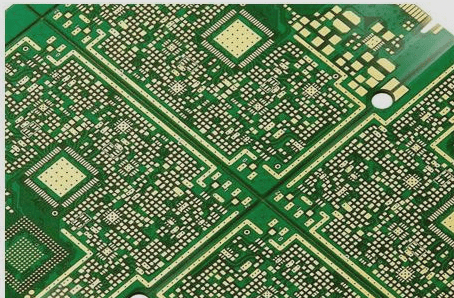

Metallographic Slicing Production Process in PCB Manufacturing

Printed circuit boards (PCBs) play a crucial role in electronic devices, requiring thorough quality assessment techniques. The PCB manufacturing process is intricate, and any quality issues can lead to scrapping the board. Inspection methods include visual examination and metallographic slicing technology, which is favored for its cost-effectiveness and broad applicability. This technique allows for evaluating various properties of PCBs like resin contamination, plating cracks, and solder coating conditions.

Microsectioning Production Process

- Extract the board for inspection

- Precision cutting to fit mold size

- Embedding, rough grinding, fine grinding

- Polishing, micro-etching, observation

Role of Metallographic Slicing in PCB Production

Metallographic slicing is essential for quality inspection and control in the PCB production process. It helps in assessing the quality of semi-finished boards at each stage, ensuring the reliability of the final product. This technology plays a crucial role in inspecting hole roughness after drilling and detecting resin contamination and etchback effects.

Impact of Drilling on Printed Circuit Board Quality

During drilling, the printed circuit board faces high temperatures, which can lead to resin contamination if not properly managed. The accumulation of heat during drilling can cause the epoxy resin to reach temperatures that result in contamination. If multilayer boards are drilled without subsequent etching, signal line connections may be compromised, affecting overall board quality.

Resolving Quality Issues in PCB Production

Quality issues are common in the production of printed circuit boards. Metallographic slicing technology plays a crucial role in quickly identifying and addressing these problems, leading to cost savings, on-time delivery, and improved customer satisfaction.

Plating Void Problems

- Poor Copper Deposition:

- Symmetrical ring-shaped voids in holes indicate a lack of copper due to trapped bubbles during the deposition process.

- Dry Film Intrusion into Holes:

- No copper present at the air port position due to dry film flowing into holes during processing.

Undercutting Issues

During the etching process, unnecessary copper is removed, leading to undercutting problems. Side etching can compromise trace accuracy and result in protruding edges, potentially causing short circuits.

Mitigating Side Etching

To address side etching, strict controls over factors like copper concentration, pH levels, temperature, and spraying methods are crucial. Implementing targeted improvements in these areas can effectively reduce side erosion issues.

Conclusion

Quality control is essential at every stage of printed circuit board production. Metallographic slicing technology aids in identifying root causes of quality issues, enabling process optimization and adherence to production standards.