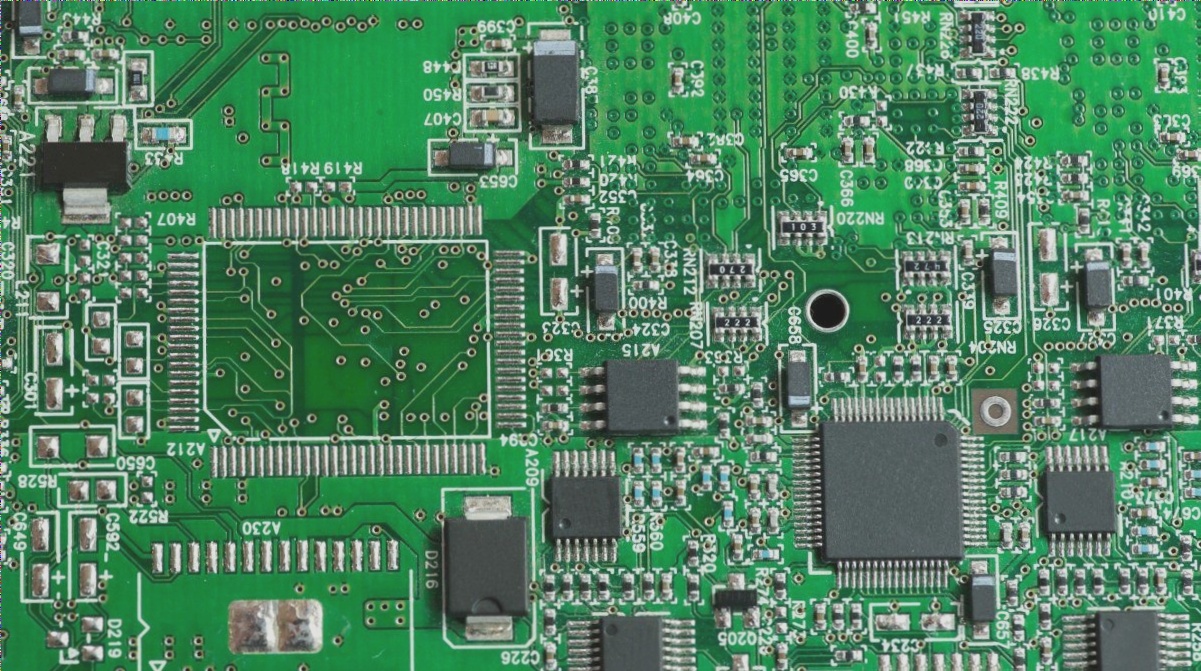

Advancements in Screen Printing Technology for PCB Manufacturing

Screen printing technology in the PCB industry has seen significant advancements, with new materials, processes, and equipment continuously improving. These developments have made screen printing suitable for high-density PCB production, offering various benefits to the manufacturing process.

Key Aspects of Screen Printing in PCB Manufacturing:

- Wire Mesh: The screen, a crucial component of screen printing plates, influences ink fluidity, printing thickness, and screen durability. It is essential for quality switch manufacturing technology.

- Printing Plate Photosensitive Material: Diazo sensitizers and photosensitive films are commonly used in creating high-quality printing plates, offering benefits such as uniform film thickness, high resolution, and strong adhesion.

- Screen Frame: The material and shape of the screen frame are vital for maintaining tension consistency. High-tensile aluminum mesh frames are widely used for their strength and durability.

Screen printing technology continues to play a crucial role in PCB manufacturing by enhancing efficiency, reducing costs, and improving processing quality. Ongoing research on screen printing materials, including functional inks, has diversified its applications. Examples include silver paste printing in membrane switch manufacturing and stencil manufacturing of solder paste in SMT technology.

For more information on PCB fabrication and the latest advancements in screen printing technology, visit Well Circuits.