Key Considerations for High-Frequency PCB Substrates

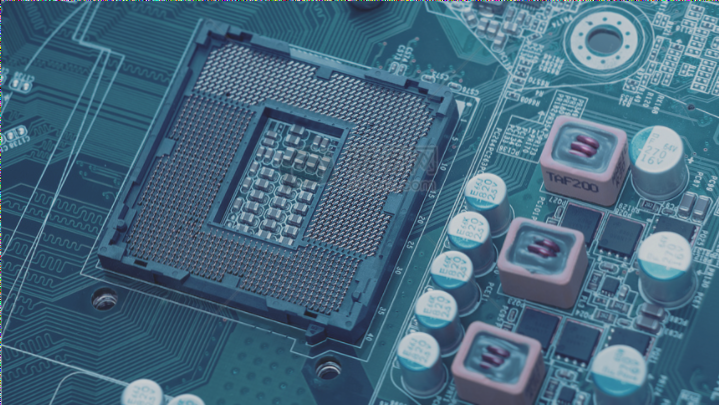

- Dielectric Constant (Dk): The Dk should be small and stable, as a lower Dk allows for faster signal transmission.

- Dielectric Loss: A lower Dk helps minimize signal loss by reducing dielectric loss.

Material Requirements for High-Frequency PCB Substrates

When selecting PCB substrates for high-frequency applications, several material characteristics play a crucial role:

- The thermal expansion coefficient of copper foil should be consistent, with minimal water absorption.

- Factors like heat resistance, chemical resistance, impact strength, and peel strength are essential considerations.

Frequency Bands and Substrate Selection

High-frequency boards typically operate above 1GHz. Fluorine-based dielectrics like Teflon are favored for frequencies above 5GHz, while FR-4 substrates are suitable for the 1GHz to 10GHz range.

Optimal Material Choice

Teflon stands out as the preferred material for frequencies exceeding 10GHz, but material selection ultimately depends on specific customer requirements.

Performance Factors in High-Frequency PCBs

- Benefits: High-frequency PCBs and low-frequency power supply circuits both exhibit voltage gain effects. Resonant frequency and passband are crucial concepts in amplifier circuits.

- Selectivity: Refers to a circuit’s ability to select desired signals and reject unwanted ones.

- Noise Figure: Reflects the comparison between input and output signal noise in an amplification circuit.

- Stability: Ensuring key performance maintenance under varying conditions is vital for high-frequency PCBs.