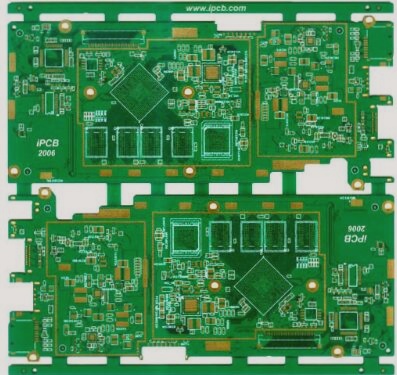

Key Features of High-Reliability PCB Circuit Boards

-

25 Micron Hole Wall Copper Thickness Benefits:

This thickness improves z-axis expansion resistance, enhancing reliability. Without it, there’s a risk of blow holes, connectivity issues, or failure under load conditions.

-

No Welding Repair or Open Circuit Repair:

Ensures a perfect circuit for reliability and safety. Improper repairs can lead to failure, even if done correctly.

-

Cleanliness Requirements Beyond IPC Specifications:

Improved PCB cleanliness enhances reliability. Residues and solder accumulation can damage the board and lead to poor solder joints.

-

Use Internationally Renowned Substrates:

Avoid “local” brands for improved reliability and performance. Inferior materials can cause delamination and poor impedance performance.

-

Strict Control of Surface Treatment Service Life:

Enhances solderability, reliability, and reduces moisture intrusion risk. Older treatments may cause soldering issues and delamination.

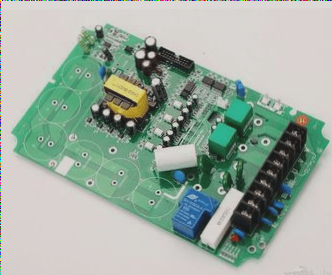

When considering PCB prices, it’s crucial to weigh various factors. While high-quality PCBs may have a higher initial cost, their long-term value makes them a worthwhile investment. Reliable performance is essential during manufacturing, assembly, and actual use of PCBs, especially in critical applications where failures can have severe repercussions.

New Information: Recent studies have shown that implementing advanced testing methods during PCB fabrication can significantly improve product reliability and reduce the risk of failures. Additionally, the use of innovative materials, such as flexible substrates, is gaining popularity in the PCB industry due to their ability to enhance performance and durability.