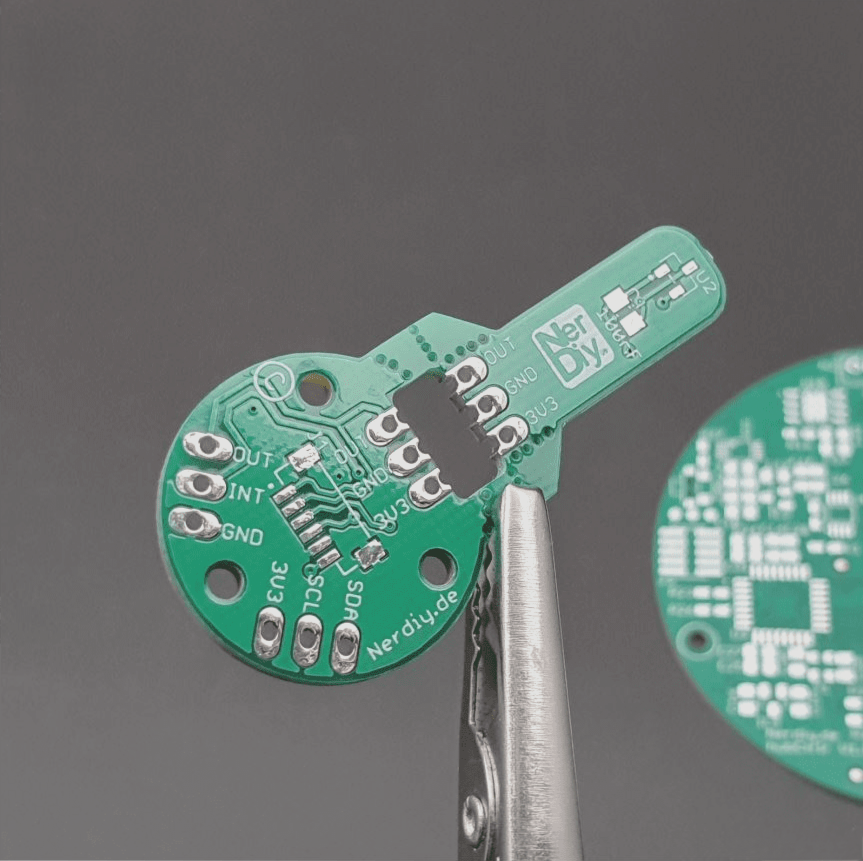

The Significance of Automotive PCBs in the Electronics Market

The automotive electronics market ranks third among circuit board manufacturers, showcasing the industry’s shift towards intelligent, high-tech solutions in vehicles. Electronic technology is extensively utilized in engine systems, chassis systems, security systems, information systems, and in-vehicle environmental systems, making automotive PCBs a critical component in modern cars.

Challenges and Opportunities in Automotive PCB Manufacturing

With the unique operating environment and high demands for safety and current in vehicles, automotive PCBs face stringent requirements for reliability and adaptability. This presents a challenge for manufacturers aiming to enter the automotive PCB market, necessitating a deep understanding of the sector and advanced technological expertise.

Specialized Practices in Automotive PCB Testing

- The Second Test Method: Some manufacturers employ this method to enhance the detection rate of defective boards post high-voltage breakdown.

- Fault-Proof Testing Systems: Integration of systems like “good board marking” and “bad board error prevention” minimizes human errors in testing machines.

- PPM Quality System Implementation: Increasingly adopted by manufacturers, this system involves statistical analysis of quality abnormalities and defect returns, aiding in targeted problem-solving.

- Comparative Testing Methods: Clients conduct tests on PCB batches from different brands to evaluate performance and select superior testers for automotive PCB testing.

- Enhancing Testing Parameters: Opting for higher voltage and threshold levels improves the detection rate of defective PCBs.

- Regular Verification of Testing Machine Parameters: Ensuring consistency and accuracy in testing processes.

Future Outlook

As the automotive industry continues to evolve with advanced electronics, the demand for high-quality, reliable automotive PCBs will only increase. Manufacturers must stay ahead by investing in technology and processes that meet the stringent requirements of this dynamic market.

Testing Machine Maintenance for PCB Companies

As testing machines are used over time, their internal resistance and other test parameters may drift, affecting testing accuracy. To ensure precision, it is crucial for PCB companies to regularly adjust these parameters. Many leading PCB manufacturers perform maintenance every six months to a year, fine-tuning internal performance settings as needed.

The PCB industry’s ongoing goal of achieving “zero defects” in automotive PCBs remains a priority. Despite challenges posed by processing equipment and raw materials, the top 100 PCB companies worldwide are actively exploring strategies to reduce PPM (parts per million) and enhance product quality.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย