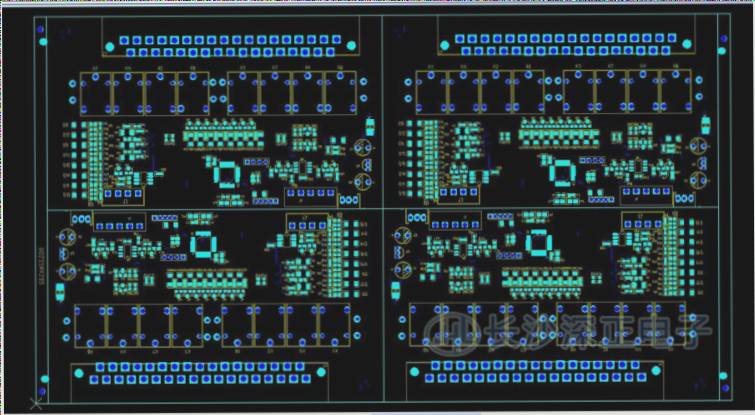

Organic Solder Mask Development in PCB Fabrication

- The PCB requires protective measures on the copper surface to ensure solderability, especially for high-density assemblies.

- Introduction of the Entek process faced challenges initially with limited weather resistance, but subsequent improvements have made organic solder masks a more viable option.

- Organic solder masks are now based on compounds like BTA, AI, and ABI, offering cost advantages and lead-free assembly benefits.

- Copper protection agents like CU-XX from ENTHON form stable compounds with metals, creating a protective film on copper surfaces to prevent oxidation and maintain solderability.

- Various organic compounds form complexes with copper, preventing oxidation and preserving soldering properties, with acetic acid, formic acid, and rosin systems being commonly used.

Organic solder masks have evolved to address challenges like transparency, film thickness issues, and the need for a nitrogen-rich environment during assembly operations. With advancements in formulations and product systems, PCB manufacturers now have more reliable options to ensure efficient and effective soldering processes.