High-Speed PCB Design: Layout Essentials

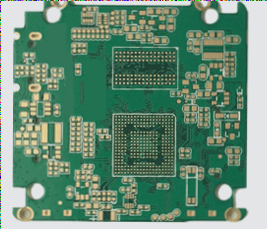

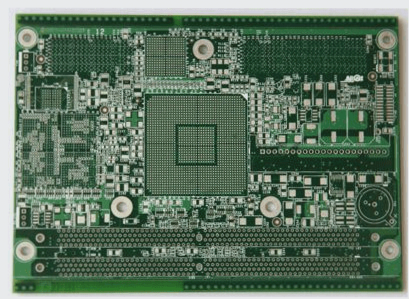

The layout of a PCB is crucial for ensuring signal quality, EMC compliance, thermal management, and overall structural integrity. Components must be strategically placed to optimize performance and adhere to safety regulations. In the realm of high-speed PCB design, a well-thought-out layout is paramount for success.

Key Concepts in PCB Layout

- Consider PCB size and specific structural requirements for devices and areas.

- Pre-layout each circuit module based on signal and power flow direction.

- Adhere to design principles for component placement within each circuit module.

Principles for Effective Layout

- Collaborate with stakeholders to address structural, SI, DFM, DFT, and EMC requirements.

- Position fixed components like connectors and mounting holes based on structural diagrams.

- Establish no-wiring and no-layout zones as per device specifications.

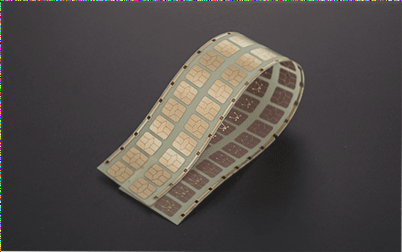

- Select process flow and layout based on PCB performance and manufacturing efficiency considerations.

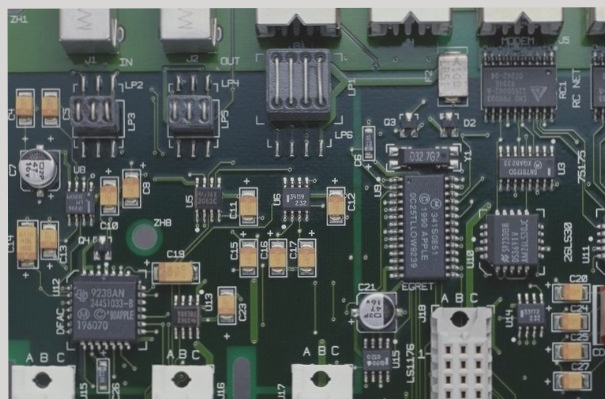

- Arrange components following the principle of “big first, then small; difficult first, then easy.”

- Ensure proper separation of signal paths, voltage levels, and signal types.

- Strive for a symmetrical modular layout within circuit sections.

Optimizing Component Layout

When placing components on a PCB, several factors need attention:

- Minimize wiring length between components to reduce interference.

- Maintain adequate spacing for components with varying potential differences.

- Secure heavy components before soldering and consider heat dissipation for heat-generating parts.

- Accommodate adjustable components while meeting structural requirements.

- Reserve space for positioning holes and brackets on the PCB.

Post-Layout Verification

After completing the layout, engineers should conduct a detailed check:

- Verify PCB size markings and alignment with structural drawings.

- Ensure components do not interfere with each other or the structural shell.

PCB Quality Check List

- Verify proper component placement.

- Ensure easy access to components for plugging or replacement.

- Check distance between thermal devices and heating elements.

- Confirm accessibility of adjustable devices and buttons.

- Ensure unobstructed installation location for the radiator.

- Verify clear signal flow direction and minimize interconnection length.

- Consider potential line interference.

- Align plug and socket design with mechanical layout.

If you require PCB manufacturing services, feel free to contact us.