—

Arlon’s materials find applications across various sectors, including wireless communication infrastructure, military and commercial avionics, and semiconductor testing and measurement equipment.

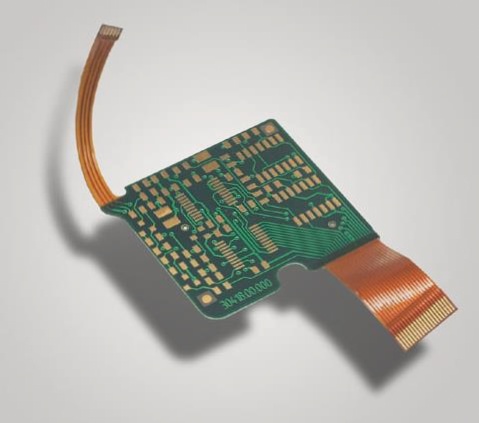

Arlon’s polyimide laminates and prepregs are ideal for producing multi-layer PCBs with exceptional thermal stability and minimal Z-direction expansion during reflow soldering. They exhibit excellent repairability in magnetic field environments. Engineered to be tougher than traditional polyimides, Arlon PCB materials are less sensitive to drilling and routing changes, offering superior thermal stability for applications with sustained high usage and lead-free soldering.

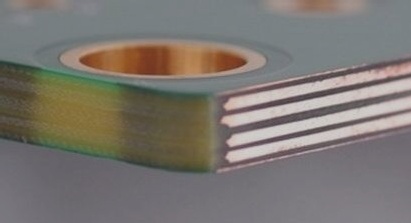

Polyimides are increasingly preferred in military and high-end commercial PCB projects due to their high reliability, capable of operating under extreme temperatures and facilitating on-site repairs even in unfavorable conditions at elevated temperatures. The high glass transition temperature (Tg 250 ℃) of Arlon PCB materials results in a low coefficient of thermal expansion (CTE) in the Z-direction, enabling the plating of high-aspect-ratio holes and enduring hotter processing compared to other commercial boards.

Key Application Areas of Arlon Materials:

1) Military and High-Reliability Applications: Critical applications like flight control demand PCB substrates with zero tolerance for failure, making polyimide materials essential due to their reliability under extreme conditions that could affect pilot safety.

2) High-Temperature Applications: Used in oil drilling probe control systems, semiconductor performance testing (known as aging testing), high-power modules, etc., Arlon’s polyimide materials excel due to their high-temperature resistance. Examples include Schlumberger’s oil drilling controls and Intel’s chip aging tests.

3) Space Applications: In satellite systems for space missions such as rocket controls, where PCBs endure significant radiation, polyimide materials ensure stable electrical characteristics and meet stringent reliability requirements. For instance, NASA/JPL’s Mars Lander missions rely on Arlon materials.

Arlon’s 25N and 25FR materials are composite dielectric materials reinforced with woven glass fibers and ceramic powder fillers, engineered for manufacturing microwave and RF multilayer circuit boards. These materials feature a non-polar thermosetting resin system to control expansion, offering low dielectric constant and loss, along with a stable thermal coefficient that ensures signal integrity across a wide temperature range. Semi-cured sheets of 25N and 25FR provide uniformity comparable to copper foil laminates, crucial for consistent multi-layer packaging applications and optimal signal integrity in finished products.

—

This revision clarifies and refines the original text for better readability and precision.