Certainly! Here are the refined and polished versions of the paragraphs you provided:

—

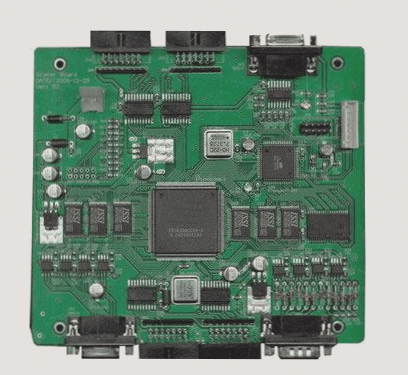

A printed circuit board (PCB) undergoes a comprehensive production process, starting with conceptual design and culminating in a fully functional PCB assembly. Initially, a network connectivity diagram is prepared to document connections. Subsequently, the PCB design is developed to implement the actual circuitry, and electrical components are procured accordingly. After assembling the parts onto the board, the circuit board is integrated into the complete system.

—

Conducting assembly inspection and validation is essential. From conception to completion, numerous intricate tasks must be meticulously executed for a successful PCB. The design of PCBs garners significant attention due to the sophisticated software tools employed in their construction, particularly at Arlon PCB, a leading manufacturer in the field.

—

Prominent applications for these advanced PCBs include sophisticated commercial and defense electronics such as avionics, semiconductor inspection, and heat sink interfacing. Arlon PCBs are crucial components in all electrical equipment, often overlooked despite their intriguing history.

—

Arlon PCB manufacturer epitomizes high performance and superior quality in printed circuit boards, making it an excellent choice for specialized electrical applications requiring advanced PCB expertise.

—

The production of a PCB involves a detailed process starting from planning and concluding with a fully operational PCB assembly. Arlon PCB stands out as the pinnacle of high-performance, high-quality printed circuit boards, ideal for diverse electricity applications, especially those demanding specialized PCB knowledge.

—

Printed circuit boards (PCBs) are critical in electrical devices, necessitating careful consideration when selecting the right components for PCB production. Arlon PCB offers cost-effective solutions and ensures the highest quality in PCB manufacturing and installation.

—

An Arlon PCB refers to a circuit board fabricated with components from Arlon LLC, renowned for its specialized materials in high-performance prepreg and laminate components used across various applications.

—

The design process for an Arlon PCB mirrors that of standard printed circuit boards but emphasizes the use of Arlon’s specific components. Employing current circuit board design tools ensures the layout incorporates all essential elements for functionality post-assembly.

—

Arlon PCB components predominantly consist of PTFE-supported fiberglass, distinguishing them from Rogers products, which utilize woven glass-supported ceramics or hydrocarbons. Both Arlon and Nelco products utilize polyimide resin, offering comparable physical properties and thermal management capabilities.

—

Utilizing Arlon materials for your printed circuit board provides significant advantages, ensuring optimal performance and reliability in diverse electronic applications.

—

In the fabrication of Arlon PCBs, the choice of Arlon materials plays a crucial role. Understanding these materials, along with essential design principles and manufacturing processes, is vital for creating high-quality Arlon printed circuit boards.

—

Feel free to let me know if you need any further adjustments or additional information!