Flexible Printed Circuit (FPC) Quality Standards

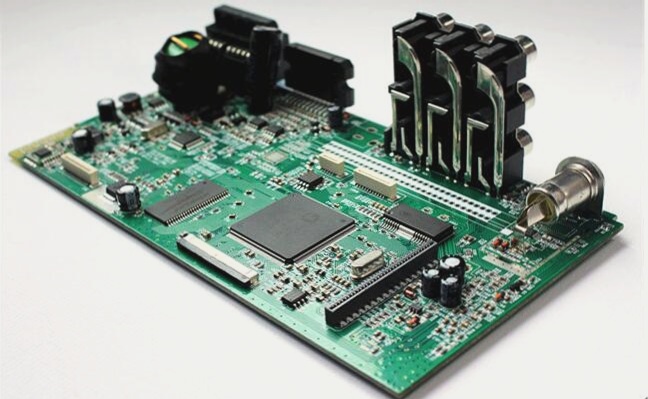

Introduction to FPC:

FPC, or Flexible Printed Circuit, is a type of circuit board known for its high wiring density, lightweight, and thin profile. It offers various advantages for electronic applications.

Criteria for Judging FPC Quality:

- Size and Thickness Standards: Flexible circuit boards have different size and thickness standards compared to rigid boards. It is crucial to measure and verify these specifications based on product requirements.

- Surface Finish and Color: The color and coverage of the external circuit board’s insulation ink play a vital role in ensuring good insulation properties.

- Weld Seam Appearance: Proper welding is essential to prevent component detachment and ensure robust connections.

Requirements for Quality FPC Boards:

- Component Functionality: Components on the board must function correctly, especially in telecommunication devices.

- Line Specifications: Line width, thickness, and spacing must adhere to specifications to avoid overheating and short circuits.

- Copper Adhesion: The copper layer should firmly adhere to prevent detachment during use.

- Oxidation Resistance: Copper surfaces need to resist oxidation to maintain efficiency and prevent premature failure.

- Electromagnetic Compatibility: FPC boards should not emit excessive electromagnetic radiation to ensure compatibility with other electronic devices.

- Shape Stability: Boards must retain their shape to prevent deformation and misalignment during installation.

- Environmental Resistance: FPC boards should withstand environmental stressors within specified limits.

- Mechanical Properties: Surface mechanical properties should meet installation requirements for reliable performance.