The Impact of Electronic Component Application on PCBA Assembly Process

The demand for electronic components is rapidly increasing, affecting the PCBA assembly process. Quality requirements for PCBA assembly are stringent, as any minor issue can lead to unusable components and higher production costs.

Characteristics of PCBA Processing Supply Chain

- Avant-garde companies in the PCBA sector have global presence and distribute products worldwide.

- Second-tier enterprises function as ODMs or PCBA contract manufacturers, engaging in product design and assembly.

- Third-tier companies supply parts to second-tier manufacturers, creating a complex web of supply relationships.

- Fourth-tier companies serve as suppliers to the third-tier, contributing to the supply chain hierarchy.

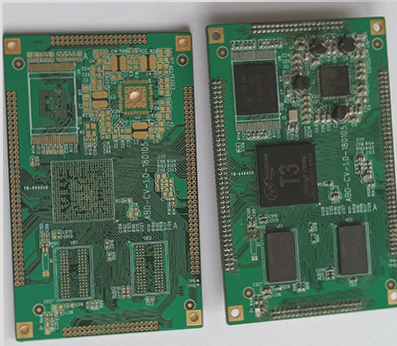

Product Landscape in PCBA Manufacturing

Companies at all levels offer a wide array of products, with complexity increasing as one moves down the supply chain. Higher-tier enterprise products exhibit greater customization, leading to reduced batch sizes for individual varieties.

Planning Challenges in PCBA Processing

Production plans are based on customer orders, influencing procurement and material preparation. Shifts in orders and deviations from plans complicate execution, impacting SMT patch processing plans.

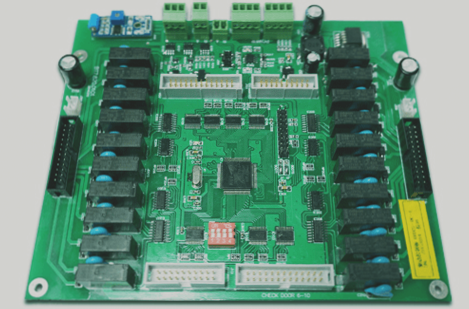

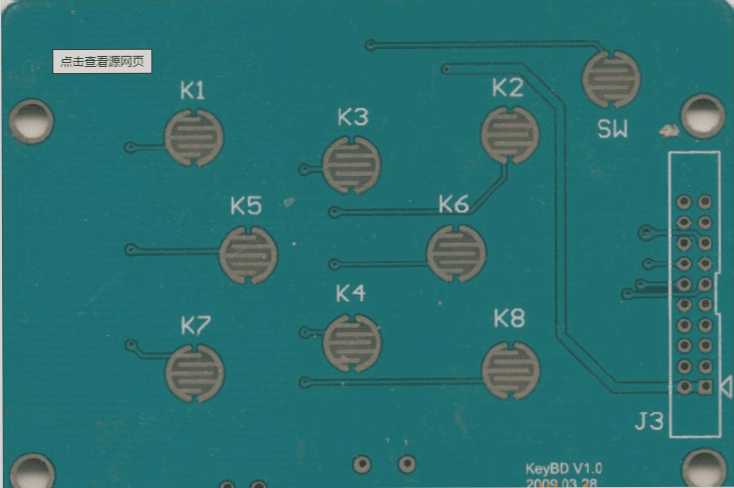

Complexities in the Production Process

Managing production tasks and controlling the process is challenging due to the volume of production data. Production lines vary widely in configuration, and outsourcing is common. Factors like materials, labor, and equipment impact product quality, posing control challenges.

PCBA Cost Calculation and Management

Calculating costs in PCBA manufacturing is complicated due to the variety of materials and products involved. Costs need to be allocated accurately throughout the production process, distinguishing between actual and standard costs for effective cost management.