Automatic Optical Detection System for PCB Board Defects

Introduction

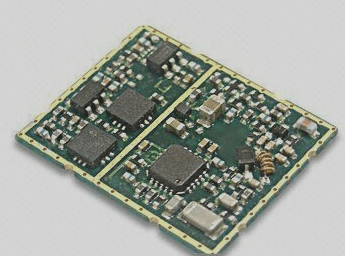

An advanced automatic optical detection system for PCB board defects has been developed, incorporating high-precision technology for real-time defect identification. This system offers a comprehensive solution for ensuring the quality and reliability of printed circuit boards (PCBs) in electronic products.

Key Features

- Two-dimensional motion platform for precise movement

- Enhanced stepper motor drive mode for accuracy

- Improved image recognition algorithm for efficient defect detection

- One-button automatic detection for increased speed

Significance of PCB Quality

PCBs play a crucial role in electronic products by integrating electronic components and facilitating their functionality. The quality of PCB boards directly impacts the performance and longevity of electronic devices, emphasizing the importance of reliable manufacturing processes.

Challenges in PCB Inspection

With the evolution of technology leading to more complex and high-performance PCBs, traditional inspection methods face limitations in terms of accessibility, cost, and efficiency. The demand for advanced defect detection systems has grown to ensure the quality of modern PCB products.

Automatic Optical Inspection Technology

Automatic Optical Inspection (AOI) technology, based on image processing, has emerged as a prominent solution for PCB defect detection. This system focuses on implementing a high-precision automatic detection system using image processing technology to enhance inspection capabilities.

System Components

The automatic PCB board defect detection system consists of a motion control module, image acquisition module, image processing module, and result analysis module. These components work together to enable efficient and accurate defect identification.

Hardware Design

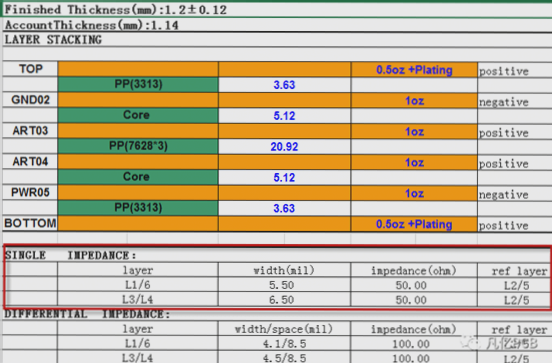

The hardware design includes essential components such as the two-dimensional motion platform, motor motion control board, CCD camera, and image capture card. Each component contributes to the system’s functionality and precision.

CCD Camera and Frame Grabber

The CCD camera’s key parameters, such as format, resolution, and sensitivity, determine the image acquisition card’s sampling frequency. The frame grabber converts analog camera signals into digital format for real-time processing and analysis.

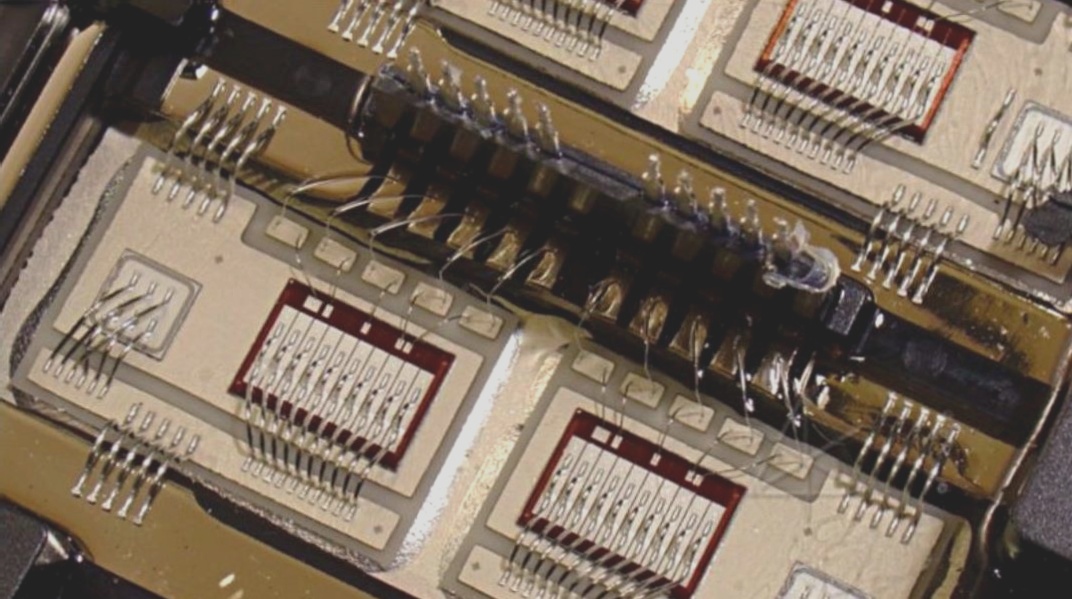

Motor Motion Controller and Precision 2D Motion Platform

The motor motion controller interfaces with the host computer to direct stepper motor operations for precise movement control. The 2D motion platform utilizes advanced components for accurate positioning and stable operation.

Motivation for Development

The continuous evolution of PCB technology necessitates innovative solutions for defect detection. By combining hardware precision and software efficiency, this automatic optical detection system offers a reliable and effective method for ensuring PCB quality.

Stepper Motor Operation in PCB Control

Stepper motor operation is all about controlling the current to excitation windings, which in turn alters the motor’s magnetic field synthesis direction to enable rotation. The torque of the motor is determined by the magnitude of these magnetic fields, while the step angle is dependent on the rotational displacement per pulse signal.

One way to enhance the resolution of the motor is through motor subdivision, which involves reducing step angles. This can be achieved by implementing methods such as constant amplitude uniform rotation of current vectors. By adopting this approach, motor vibration and noise can be minimized, ensuring stable operation – a crucial factor in PCB control.

These adjustments are made with the aim of optimizing motor performance to meet the precise operational demands in PCB manufacturing and inspection processes.