Double Probe vs Flying Probe Test Method

The flying probe test method does not rely on fixed pin patterns like traditional testers. Instead, it uses two or more probes mounted on a magnetic head that moves freely in the x-y plane. Test points are generated directly from CADI Gerber data control. These dual probes can move independently within a 4 mil distance, offering flexibility without proximity limitations.

Advantages of Flying Probe Testers

- Flexibility in test point generation

- No need for fixed pin patterns

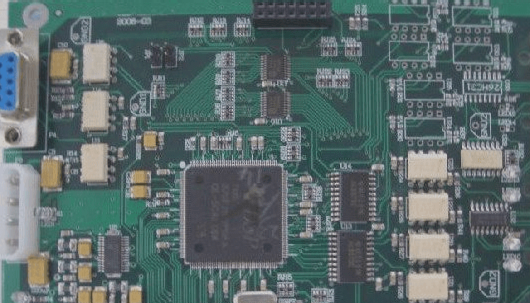

- Ability to handle complex circuit boards with lower yields

Comparison with Needle Bed Testers

While needle bed testers can efficiently test thousands of points simultaneously, flying probe testers can only handle two or four points at a time. Needle bed testers are more cost-effective for single-sided testing, but flying probe testers are preferred for complex boards with lower yields.

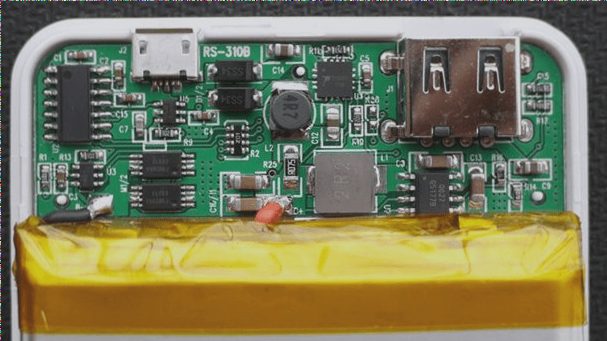

Choosing the Right Test Instrument

For bare board testing, a cost-effective approach is using a general-purpose instrument. It may be initially more expensive than a dedicated instrument, but it can reduce individual configuration costs in the long run. When selecting a grid size, it is advisable to choose a larger grid for better durability and accuracy.

Testing Levels

The typical testing levels include bare board inspection, online testing, and function detection. A universal tester can accommodate various circuit board styles and special applications, ensuring accurate and economical inspection.