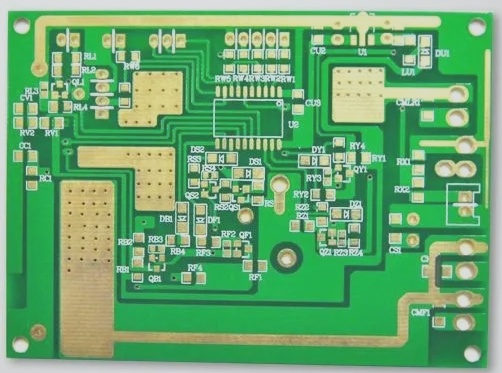

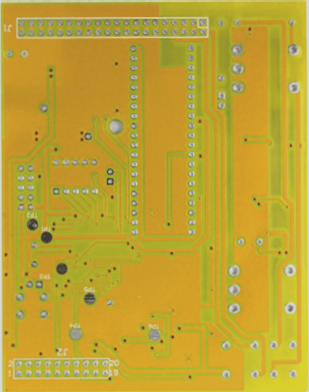

The Importance of Auxiliary Materials in PCBA Package Production

In the PCBA package production process, utilizing SMD adhesive, solder paste, stencil, and other auxiliary materials is common practice. These materials are essential in the assembly production process, significantly impacting product quality and production efficiency.

Key Factors to Consider:

- Shelf Life: The duration a material or product can maintain performance under specified conditions.

- Working Time: Maximum duration for adhesive or solder paste to retain properties after exposure.

- Viscosity: Dripping ductility and flow ability of the adhesive.

- Thixotropy Ratio: Property where adhesive and solder paste solidify into a plastic state after pressure.

- Slump: Reduction in height and spreading of solder paste after printing.

- Spread: Distance adhesive covers at room temperature after dispensing.

- Tack: Adhesion strength of solder paste to components.

- Wetting: Molten solder forming a uniform layer on the copper surface.

- No-clean Solder Paste: Leaves minimal harmless residue, eliminating the need for PCB cleaning.

- Low Temperature Paste: Solder paste with a melting temperature below 163℃.

About WellCircuits Limited:

WellCircuits Limited specializes in electronic processing, offering SMT chip processing, DIP common processing, PCBA packaging, and PCB circuit board manufacturing. With extensive experience, advanced equipment, and a robust after-sales service system, our daily SMT placement processing capacity reaches 1 million pieces, and DIP plug-in processing capacity is 200,000 pieces. We are committed to delivering top-notch electronic processing services.