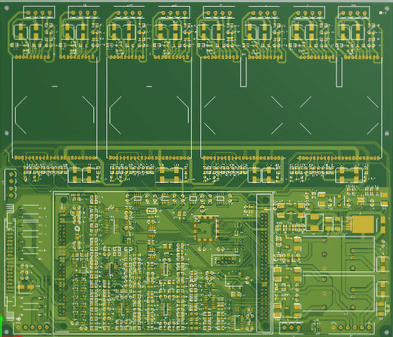

PCB Classification

PCB boards are categorized based on the number of circuit layers they have. They can be single-layer, double-layer, or multi-layer boards. Multi-layer boards can range from 4 to dozens of layers, offering more flexibility in circuit design.

Single-Sided Boards

Single-sided boards have components on one side and wires on the other. They are suitable for simpler circuits where wiring does not need to cross paths.

Double-Sided Boards

Double-sided boards have wiring on both sides connected through vias. They provide more space for complex circuits compared to single-sided boards.

Multi-Layer Boards

Multi-layer boards combine single or double-sided wiring boards to accommodate more complex circuits. They can have 4 to 6 layers, with the possibility of up to 100 layers for specialized applications.

PCB Composition

PCBs consist of various elements:

- Circuit and Pattern: Conductive paths for components and power distribution.

- Dielectric Layer: Insulation between circuit layers.

- Through Hole / Via: Connections between layers.

- Solder Resistant / Solder Mask: Insulation for non-soldered areas.

- Legend / Marking / Silk Screen: Component identification.

- Surface Finish: Protection for copper surfaces.

PCB Appearance

PCBs are made of insulated materials with copper foil patterns. They are typically green or brown, with a silk screen for component positioning. Electronic components like ICs and transistors are mounted on the board for circuit functionality.