PCB Circuit Boards: A Comprehensive Guide

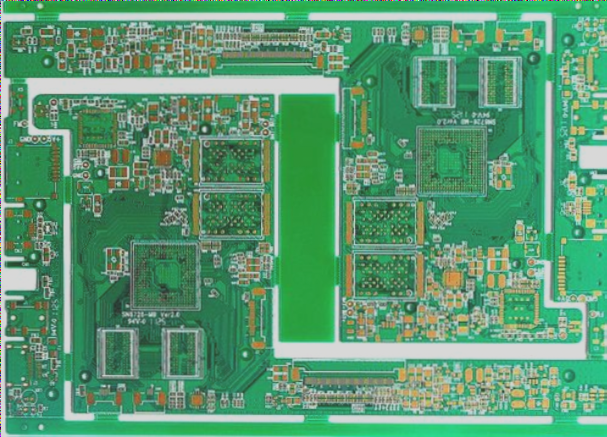

PCB, short for printed circuit board, plays a crucial role in today’s electronic industry. It utilizes an insulating board as a base material with a conductive pattern, serving as a replacement for traditional chassis in electronic devices. This enables the interconnection between electronic components through electronic printing technology, hence the name “printed” circuit board.

From electronic watches to computers, almost all electronic equipment requires PCBs for electrical interconnection. The design and manufacturing quality of PCBs directly impact the overall product quality, cost, and commercial success.

Functions of PCB

By using PCBs, manual wiring errors are reduced, and electronic components can be automatically inserted, soldered, and tested, improving productivity, reducing costs, and facilitating maintenance.

Origin of PCB

PCBs were first introduced by Austrian Paul Eisler in 1936, initially used in military radios by Americans in 1943. Since the mid-1950s, PCBs have become widely adopted, replacing direct wiring between electronic components.

Evolution of PCB

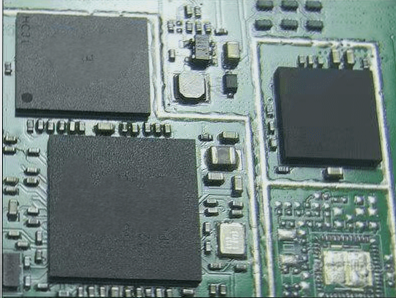

PCBs have evolved from single-sided to double-sided, multi-sided, and flexible boards, with a focus on high precision, density, and reliability. Future trends include high-speed transmission, miniaturization, and cost reduction, reflecting advancements in production technology.

- High density and precision

- Fine aperture and wire

- High reliability

- Multi-layer and high-speed transmission

- Lightweight and thin design

Overall, the development of PCBs is moving towards enhanced productivity, cost-efficiency, environmental sustainability, and adaptability to small-batch production, revolutionizing the electronic equipment industry.