As one of China’s leading manufacturers of PCB circuit boards and PCBA, WellCircuits Limited has been consistently delivering top-notch quality in PCB circuit and PCBA prototype and mass production manufacturing services worldwide, all at competitive prices. Our dedication lies in furnishing customers with premium PCB circuit boards and dependable PCBA products, underpinned by stringent standards upheld throughout the entirety of our manufacturing processes, from PCB circuit board fabrication to SMT surface mounting. Our expertise encompasses PCB board fabrication, SMT surface mounting, PCBA semi-finished products, IC programming, and PCBA functional testing—all attesting to our unwavering commitment to professionalism.

I. Challenges Faced by PCB Circuit Boards in Humid Environments

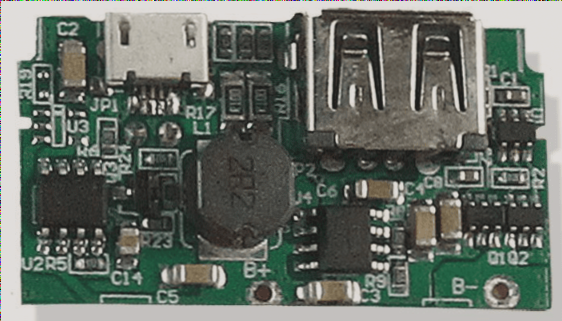

PCB circuit boards are prone to various issues when exposed to humidity, such as short circuits and signal disruptions, leading to operational failures.

How can you tell if a PCB circuit board is affected by humidity? In a humid environment, where moisture levels in the air are high, water droplets can form and fall onto the PCB circuit board. These droplets disperse across the board, clinging to the pins or printed lines of electronic components. When the printed lines absorb moisture, especially the delicate signal transmission lines, they can degrade over time, appearing moldy or broken. Consequently, the circuit board may fail to function properly when put into operation.

The failures attributed to humidity can be categorized into three main factors: changes in PCB circuit board parameters leading to failure, short-circuiting of the circuit due to environmental conditions, and disruption of signal processing or transmission lines, resulting in circuit board failure.

II. Key Advantages of Utilizing Printed Circuit Boards

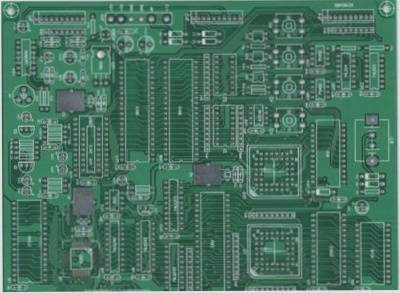

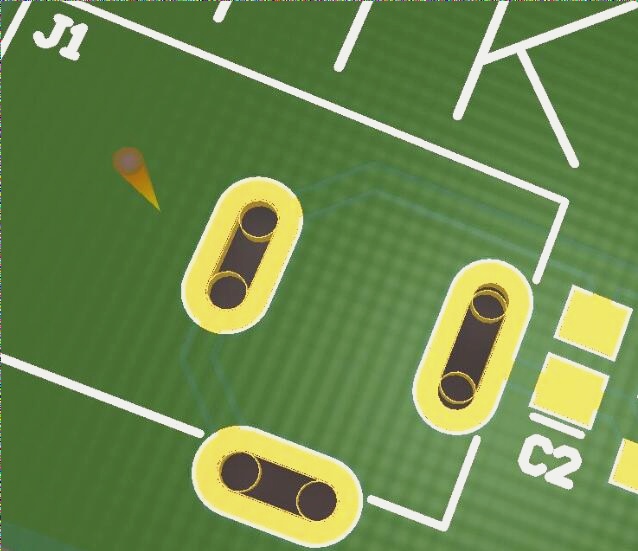

As a crucial electronic component, the PCB circuit board serves as the structural foundation for electronic components. Manufactured using electronic printing technology, it earns the moniker of a “printed” circuit board.

The primary advantages of employing PCB circuit boards include:

– Reproducibility and consistency in graphics reduce wiring and assembly errors, thus saving time on equipment maintenance, debugging, and inspection.

– Standardized design facilitates interchangeability.

– High wiring density, compact size, and lightweight nature promote the miniaturization of electronic devices.

– Enables mechanization and automated production, enhancing labor productivity and reducing the cost of electronic equipment.

The foregoing highlights the challenges posed by humidity to PCB circuit boards, along with the advantages of using printed circuit boards. We trust this information proves valuable to those in need and encourage continued support for WellCircuits Limited.

I. Challenges Faced by PCB Circuit Boards in Humid Environments

PCB circuit boards are prone to various issues when exposed to humidity, such as short circuits and signal disruptions, leading to operational failures.

How can you tell if a PCB circuit board is affected by humidity? In a humid environment, where moisture levels in the air are high, water droplets can form and fall onto the PCB circuit board. These droplets disperse across the board, clinging to the pins or printed lines of electronic components. When the printed lines absorb moisture, especially the delicate signal transmission lines, they can degrade over time, appearing moldy or broken. Consequently, the circuit board may fail to function properly when put into operation.

The failures attributed to humidity can be categorized into three main factors: changes in PCB circuit board parameters leading to failure, short-circuiting of the circuit due to environmental conditions, and disruption of signal processing or transmission lines, resulting in circuit board failure.

II. Key Advantages of Utilizing Printed Circuit Boards

As a crucial electronic component, the PCB circuit board serves as the structural foundation for electronic components. Manufactured using electronic printing technology, it earns the moniker of a “printed” circuit board.

The primary advantages of employing PCB circuit boards include:

– Reproducibility and consistency in graphics reduce wiring and assembly errors, thus saving time on equipment maintenance, debugging, and inspection.

– Standardized design facilitates interchangeability.

– High wiring density, compact size, and lightweight nature promote the miniaturization of electronic devices.

– Enables mechanization and automated production, enhancing labor productivity and reducing the cost of electronic equipment.

The foregoing highlights the challenges posed by humidity to PCB circuit boards, along with the advantages of using printed circuit boards. We trust this information proves valuable to those in need and encourage continued support for WellCircuits Limited.