FPC: The Future of Flexible Circuit Boards

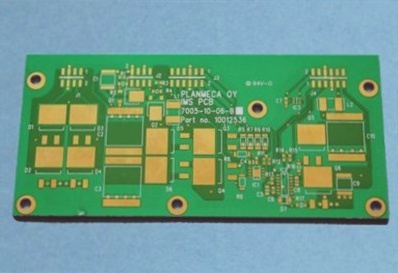

- Introduction: FPC (flexible circuit board) is an exceptional type of printed circuit board made from polyimide or polyester film, known for its high reliability and bendability.

- Key Features:

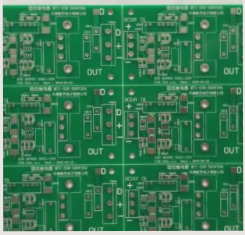

- High wiring density

- Lightweight and thin profile

- Excellent bendability

- Challenges: Preventing excessive openings and short circuits during production is crucial to avoid low yields and issues from rough processes like drilling and cutting.

- Material Selection: Addressing FPC board scrap and replenishment challenges is essential for optimal performance in customer applications.

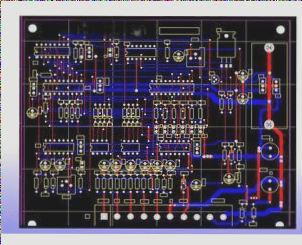

- Pre-production Pretreatment: Pre-production pretreatment plays a vital role in ensuring optimal outcomes for flexible circuit boards. Engineers evaluate the FPC board, prepare materials, and adapt CAD drawings for production.

Production Process Overview

From cutting to final inspection and shipment, the production process involves various steps in both double and single panel systems.

Characteristics of FPC:

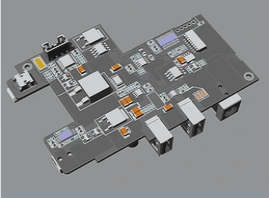

- Short: Reduces assembly time by integrating all lines.

- Small: Compact design decreases product volume for enhanced portability.

- Light: Lighter than traditional PCBs, reducing the final product weight.

- Thin: Thinner than PCBs, allowing for increased flexibility and 3D assembly in tight spaces.

Future Prospects:

FPC innovation focuses on enhancing flexibility, durability, affordability, and technological advancements to meet evolving market demands.