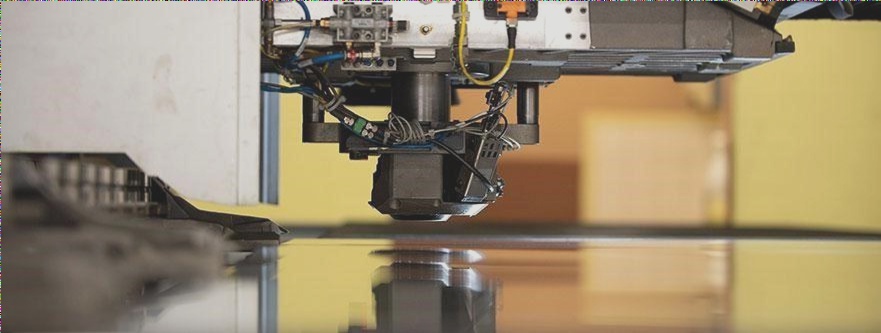

Metal Stamping: A Comprehensive Guide

Latest Trends and Insights in Metal Stamping Industry

- Advanced Automation Technologies

- Increased Focus on Sustainability

- Integration of IoT and Data Analytics

Source: Falcon

Metal stamping is a crucial manufacturing process utilized across various industries in the United States and Canada. From automotive to aerospace and medical sectors, metal stamping plays a vital role in producing metal components.

While metal stamping enables high-volume production and quick turnaround times, it can sometimes be costly.

In this article, we delve into the fundamentals of metal stamping, the available metal stamping services, and strategies to minimize metal stamping expenses for your business. Keep reading to explore more.

Understanding CNC Metal Stamping

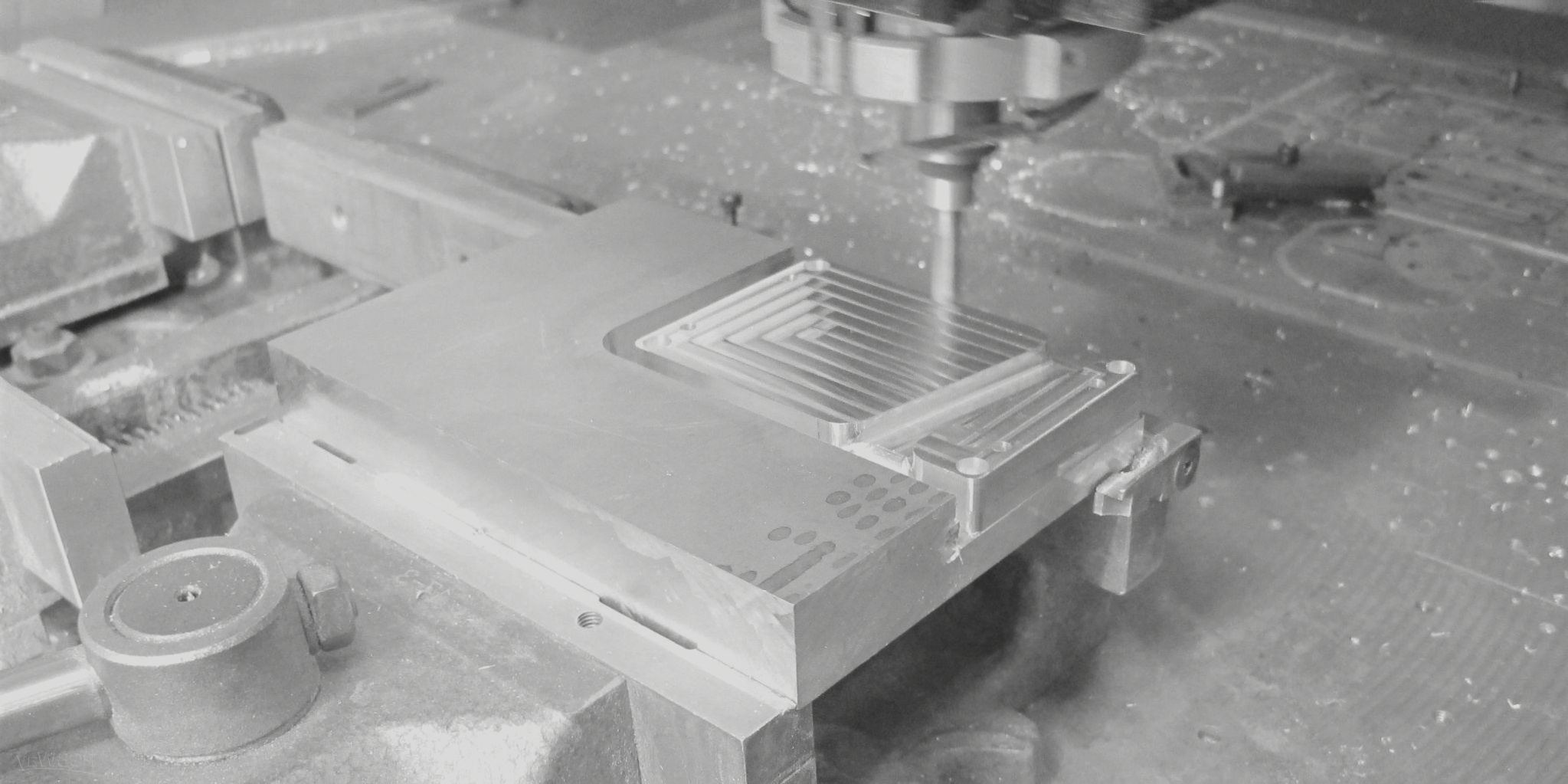

CNC metal stamping is a manufacturing method that transforms flat metal sheets into various shapes to create metal parts. Processes involved include punching, blanking, embossing, bending, flanging, and coining, often carried out using cold metal stamping machines for precise results.

Metal stamping is recognized for its cost-effectiveness and high-speed production capabilities, facilitating the mass production of identical metal components for short or long runs.

Essentials of Metal Stamping

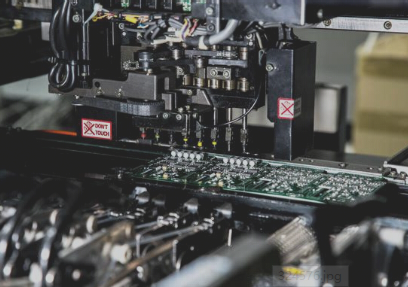

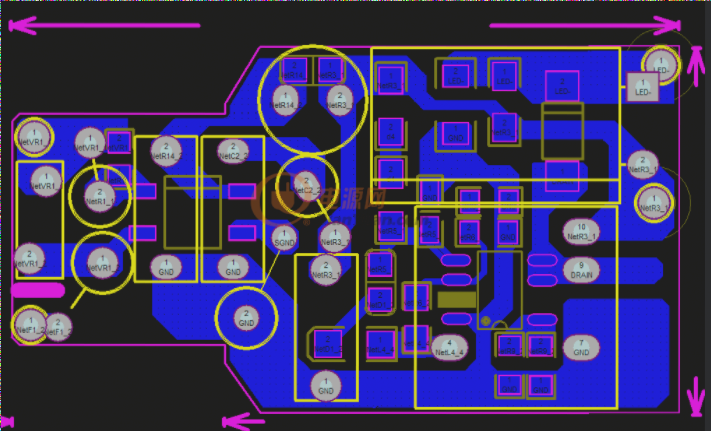

Most metal stamping firms adhere to a standardized process where a quality metal sheet is fed into a stamping press, either in coil or blank form.

Within the CNC machine, a tool and die surface shapes the metal into the desired form, employing various metal stamping processes based on specific requirements.

Types of Metal Stamping Techniques

There are three main types of metal stamping techniques: progressive die stamping, fourslide stamping, and deep draw stamping. Let’s explore each method:

Progressive Die Stamping

Source: gestiondecompras

Progressive die stamping involves multiple stations, each with a specific function. As the metal strip progresses through the press, it undergoes various cuts, punches, or bends at each station, creating an efficient, multi-step process.

Fourslide Stamping

Also known as multi-slide stamping, this technique utilizes four slides for intricate cuts simultaneously, making it ideal for complex component creation.

During the process, sheet metal is fed into the fourslide machine, where each tool bends the metal according to the design.

Deep Draw Stamping

Source: Gem Manufacturing

Deep draw stamping involves pulling sheet metal into a die using a punch, particularly useful for creating parts with varying diameters. This technique is cost-effective and commonly used in automotive, aerospace, and cookware industries.

Advantages and Disadvantages of Metal Stamping

Similar to any manufacturing process, metal stamping offers both advantages and disadvantages. Here are the key benefits:

Precision

Metal stamping ensures high precision in part production, meeting safety and functionality specifications accurately. Automated processes and stamping simulation technologies detect and rectify flaws before production, guaranteeing flawless results.

Cost-Effectiveness

Metal stamping excels in producing intricate parts at a low cost, unlike some other fabrication methods. Automation reduces manual labor, cutting overall labor costs and subsequently lowering component prices.

Speed

Metal Stamping: A Fast and Versatile Manufacturing Process

Metal stamping is a rapid manufacturing process that offers a quick return on investment. With equipment capable of thousands of strokes per minute, it is ideal for high-volume production runs, allowing companies to bring new products to market swiftly.

Flexibility in Metal Stamping

Metal stamping is incredibly versatile, capable of producing a wide range of shapes and components, from tiny parts to complex geometries.

Challenges and Cost Reduction Strategies

While metal stamping has many advantages, it comes with challenges such as high initial costs and die production. To reduce costs, consider using softer raw materials, optimizing the manufacturing process, and manufacturing in larger volumes.

Industries Benefiting from Metal Stamping

Metal stamping serves various industries, including aerospace, medical devices, automotive, electrical distribution, and appliances.

Preferred Metals for Stamping

Copper, bronze, nickel, and brass are commonly used metals in stamping due to their versatility and properties suitable for different applications.

Applications in Different Industries

Aerospace: Precision metal stamping is crucial for aerospace components, ensuring compliance with safety standards.

Medical Devices: Metal stamping creates components for medical devices, adhering to strict safety regulations.

Automotive: Essential for producing structural components in vehicle manufacturing.

Electrical Distribution: Used in creating parts for power equipment like transformers.

Appliances: Metal stamping plays a vital role in producing various commercial and residential appliances.

The Significance of Metal Stamping

Metal stamping is utilized to manufacture a variety of products with thin walls and smooth finishes, serving industrial and consumer needs.