1. As early as a few years ago, due to its unique properties, FPC has become increasingly vital in the design of slide and foldable phones.

2. The demand for sliding cover mobile phone panels and multilayer boards for folding phones is on the rise.

3. Controlling the quality of FPC manufacturers is crucial throughout this process.

4. What are the advantages of FPC?

With the miniaturization, high-speed capabilities, and digitization of electronic products, there has been rapid growth in personal communication devices, imitation mobile phones, and 3G communications, alongside a demand for networked intelligent information terminals (such as computers, TVs, telephones, and faxes) that cater to mobile communication needs. The requirements for FPC lifespan and impedance in sliding and foldable mobile phones are becoming increasingly precise. Therefore, for FPC manufacturers, effectively controlling the production of such products is crucial.

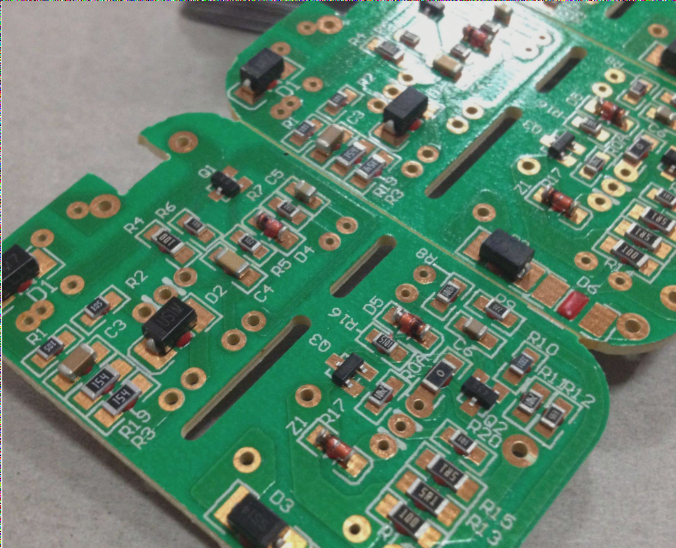

FPC (Flexible Printed Circuit, also known as flexible printed circuit board or FWPC) possesses the following characteristics:

(1) Excellent flexibility: It can be bent and deformed freely, with a small coiling radius, allowing movement in three dimensions—X, Y, and Z;

(2) Compact size: Lightweight and thin, it maximizes the limited space in instruments and meets the miniaturization and lightweight demands of electronic products;

(3) Low weight: The soft board is designed based on current carrying capacity rather than mechanical strength, resulting in a relatively lighter weight;

(4) Strong sealing capability: It employs a low-tension sealing design, enabling it to withstand harsh environmental conditions;

(5) Stable transmission characteristics: Wire spacing can be customized based on electrical parameters, ensuring an optimal layout;

(6) Superior assembly processability: It offers excellent performance for free and overall terminations, making it suitable for soldering, plugging, and three-dimensional wiring and connections;

(7) High insulation performance: The base materials, PI and PET, used in flexible boards have high insulation strength, while a cover film enhances overall insulation.

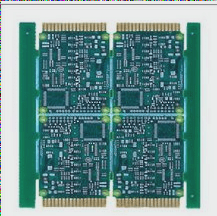

In recent years, FPC’s unique characteristics have become increasingly significant in the design of sliding and foldable phones. As consumer expectations for durability grow, our company has ramped up orders for sliding cover mobile phone panels and multilayer boards for folding devices. To enhance quality and personnel training, we focus specifically on design and layout concepts, material selection, and process maintenance during production to minimize defects and improve first-pass yield rates.

2. The demand for sliding cover mobile phone panels and multilayer boards for folding phones is on the rise.

3. Controlling the quality of FPC manufacturers is crucial throughout this process.

4. What are the advantages of FPC?

With the miniaturization, high-speed capabilities, and digitization of electronic products, there has been rapid growth in personal communication devices, imitation mobile phones, and 3G communications, alongside a demand for networked intelligent information terminals (such as computers, TVs, telephones, and faxes) that cater to mobile communication needs. The requirements for FPC lifespan and impedance in sliding and foldable mobile phones are becoming increasingly precise. Therefore, for FPC manufacturers, effectively controlling the production of such products is crucial.

FPC (Flexible Printed Circuit, also known as flexible printed circuit board or FWPC) possesses the following characteristics:

(1) Excellent flexibility: It can be bent and deformed freely, with a small coiling radius, allowing movement in three dimensions—X, Y, and Z;

(2) Compact size: Lightweight and thin, it maximizes the limited space in instruments and meets the miniaturization and lightweight demands of electronic products;

(3) Low weight: The soft board is designed based on current carrying capacity rather than mechanical strength, resulting in a relatively lighter weight;

(4) Strong sealing capability: It employs a low-tension sealing design, enabling it to withstand harsh environmental conditions;

(5) Stable transmission characteristics: Wire spacing can be customized based on electrical parameters, ensuring an optimal layout;

(6) Superior assembly processability: It offers excellent performance for free and overall terminations, making it suitable for soldering, plugging, and three-dimensional wiring and connections;

(7) High insulation performance: The base materials, PI and PET, used in flexible boards have high insulation strength, while a cover film enhances overall insulation.

In recent years, FPC’s unique characteristics have become increasingly significant in the design of sliding and foldable phones. As consumer expectations for durability grow, our company has ramped up orders for sliding cover mobile phone panels and multilayer boards for folding devices. To enhance quality and personnel training, we focus specifically on design and layout concepts, material selection, and process maintenance during production to minimize defects and improve first-pass yield rates.