Efficient Space Management in PCB Design

When embarking on a new PCB schematic, one of the primary challenges is effectively utilizing the available space. The strategy you adopt will be influenced by factors such as the project’s size, complexity, target audience, relevant standards, and lifecycle considerations. Whether you intend to print the schematic will also impact your space allocation decisions.

Initially, you must decide whether to use a single sheet or multiple sheets. For smaller projects, starting with a single A4 sheet is practical. As your design expands, transitioning to A3 allows for printing and offers more room for growth as the project develops.

Organizing Your Schematic Logic

Creating a well-structured schematic design is crucial for clarity and comprehension. Here are some key guidelines:

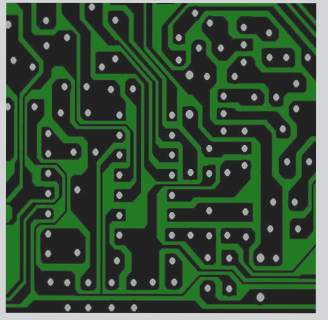

- Divide the schematic into logical blocks: Categorize components into blocks like power supply, microcontroller, input connectors, and output connectors. While there are no strict rules for partitioning, aligning divisions with your project’s structure is essential.

- Ensure a left-to-right flow: Arrange components so that the logical flow progresses from left to right. Inputs should be on the left, while outputs should be on the right, both within and outside the blocks.

It’s vital to maintain a clear and logical sequence throughout the schematic to ensure easy comprehension. Adding concise yet informative notes to explain specific sections is recommended. Consider using hierarchical sheets for intricate designs to enhance organization.

Key Practices for Clarity

- Avoid routing wires beneath components.

- Utilize horizontal or vertical wire routes; reserve free-angle lines for indicating swapped signals.

- Direct ground connections downward and power connections upward.

- Use net labels for simplified connections.

- Limit junctions to three connections to minimize complexity.

- Employ graphical lines and text for clear block descriptions.

Optimizing Multi-Sheet Schematics

For larger designs, dividing the schematic into multiple sheets enhances organization. Each sheet represents a logical block, simplifying the overall structure. Numbering sheets based on their function aids in easy referencing and navigation.

Understanding Net Labels

Net labels streamline connections in your schematic by assigning logical names to wires without physical links. They ensure consistency in naming connections across the design. There are three types of net labels: local, global, and hierarchical, each serving specific connectivity purposes.

Maintaining Consistency and Symmetry

Consistency and Symmetry in Schematics

Ensuring consistency and symmetry in your schematic layout is crucial for clarity and organization. It is recommended to maintain a uniform style for components and arrange similar elements symmetrically. For instance, when dealing with multiple components of the same type, such as capacitors, keeping them in a consistent pattern aids in easy comprehension.

Metadata Section

Every schematic should contain a metadata section or a title block. This section should include basic information like project name, revision, and date, even if you are the sole viewer. This practice ensures quick identification of the schematic version when needed in the future.

Understanding Notes in Schematics

Adding appropriate notes to your schematic is essential for explaining each component clearly. Utilize free text notes for general descriptions and component-specific notes for detailed information like part numbers and specifications. Design tools offer options for visible and invisible notes, which can be beneficial for bill of materials and project documentation.

Importance of Decoupling Capacitors

Decoupling capacitors play a crucial role in stabilizing voltage and reducing noise in IC circuits. Placing these capacitors near the power pins of the ICs they support is common practice. However, some designs may opt to group them separately. Consistency in placement and clear documentation of their function are key, especially when deviating from the standard placement.

General Guidelines and Flexibility

While the suggestions provided are not strict rules, following them enhances clarity and professionalism in your designs. Most design software may not enforce these guidelines, but adhering to them is still recommended. If you decide to diverge from these practices, ensure you have valid reasons for doing so.

Advanced Tip: Utilizing Net Ties

In certain scenarios, connecting two nets without merging them into one is necessary. For instance, connecting a trace antenna to ground separately can prevent interference with the antenna’s performance. Net ties enable the connection of two distinct nets while maintaining their individual characteristics, especially useful in antenna or specialized component designs.

If you have any inquiries regarding PCB or PCBA design, feel free to contact us via email at info@wellcircuits.com.