Manufacturing Instructions for FPC Flexible Circuit Boards

1. The production department and outsourcing units receive detailed information on materials, process flow, parameters, inspection methods, and quality requirements for FPC flexible circuit board products through Manufacturing Instructions (MI).

2. Efficient production management is crucial for overseeing the delivery cycle of FPC flexible circuit boards, from order placement to completion. Utilizing an ERP system streamlines production scheduling and work-in-progress management, ensuring timely delivery and meeting customer demands.

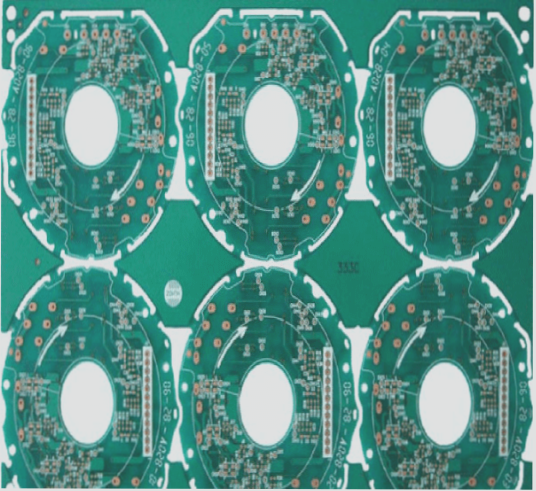

3. FPC boards are commonly classified based on the number of layers, such as single-sided, double-sided, and four-layer boards. Each category requires specific instructions regarding materials, processes, parameters, and quality standards to be communicated effectively to production units.

Production Process Variations

- For products with four-layer boards or fewer, the production process is straightforward, allowing for uninterrupted completion of the production process card.

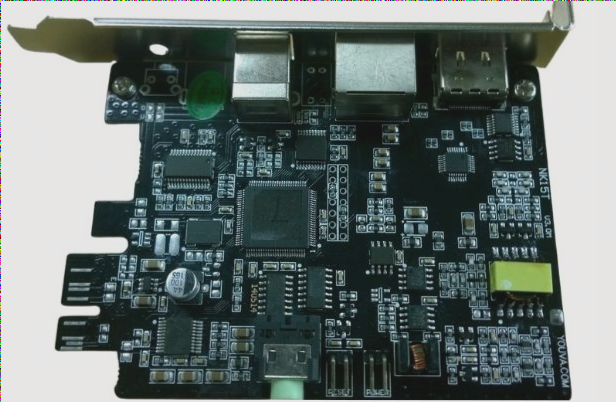

- Complex products with blind and buried vias and more than six layers require distinct circuit diagrams, process flows, and parameters for inner and outer layers. Specialized molds, films, and equipment are essential, leading to the creation of specific production instructions and process cards.

- During production, multilayer boards are identified with unique inner codes, managed through different production process cards to track progress effectively.

Challenges in Production Management

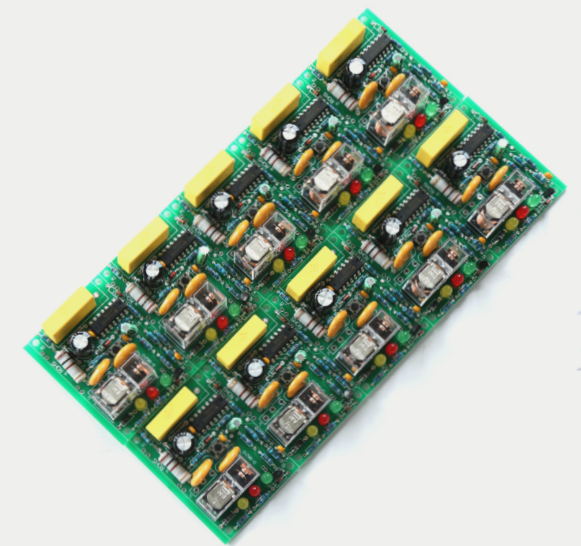

1. Managing online products with diverse models necessitates efficient procedures for counting, scrapping, and repairs, which can be challenging for standard ERP systems.

2. Detailed production operation plans provide valuable information but can be complex to execute accurately, especially in the intricate process flow of FPC boards.

3. The engineering data and production of complex FPC multilayer boards require significant time investment, often against tight customer delivery deadlines.

4. The dynamic nature of the FPC industry requires frequent design changes and version updates, necessitating revisions to manufacturing instructions and process flow cards accordingly.