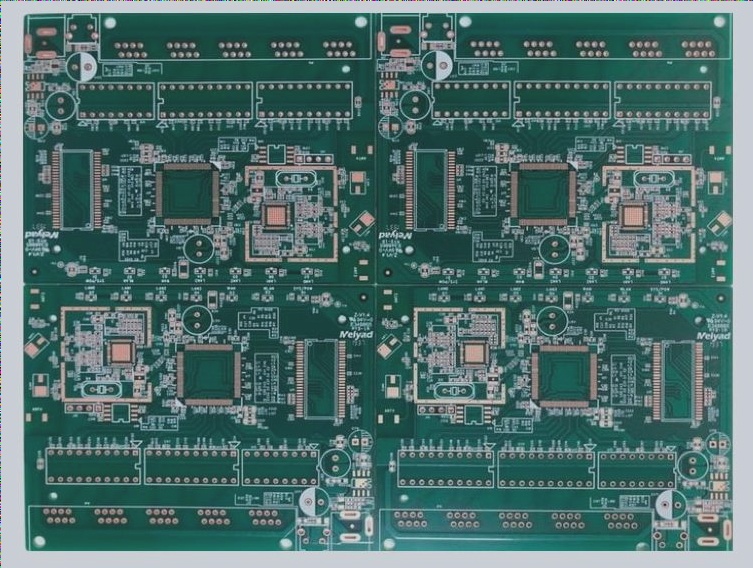

PCB Soldering: Connecting Components for Electronic Manufacturing

PCB soldering is a crucial process in electronic manufacturing, where soldering points are heated to bond with the copper foil on the circuit board, establishing both electrical connections and mechanical fixation.

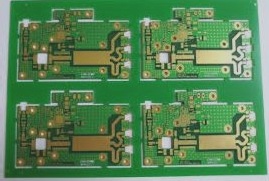

Common PCB Soldering Methods

- Manual Soldering: This fundamental method involves using a soldering iron to melt solder wire and apply it to components. It is cost-effective but requires precise temperature control.

- Wave Soldering: An automated technique for mass production, providing high efficiency and consistent quality but may be costly.

- Hot Air Soldering Iron Soldering: Utilizes a hot air soldering iron for high-quality joints, albeit requiring advanced skills and slower speed.

- Reflow Soldering: Based on Surface-Mount Technology, offering consistent joint quality through controlled heating.

The Importance of Circuit Board Soldering

- Connect Electronic Components: PCB soldering establishes connections between components and the board, crucial for performance and reliability.

- Enhance Reliability: Proper soldering prevents issues like loose connections, faults, and short circuits that can disrupt circuit board operation.

- Improve Product Performance: Well-soldered components ensure robust connections, enhancing overall product performance.

Effective PCB soldering is essential for connecting electronic components, ensuring optimal performance and reliability in electronic products.