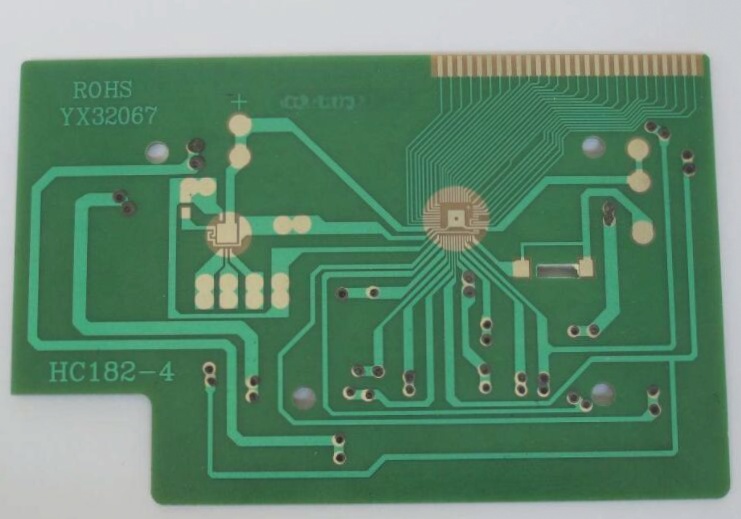

PCB Layout Best Practices for Improved Design Quality

- Today’s PCB design faces strict layout requirements that determine wiring structure, power distribution, and noise management.

- Engineers spend a significant amount of time on layout, which can consume over 50% of the total design time.

- Layout steps and rules are essential, but factors like heat dissipation and mechanical performance must also be considered.

- Start layout with a clear system schematic understanding, categorize components, and plan power and signal pin placements.

- Divide the PCB into digital and analog areas, place components accordingly, and sequence placement strategically.

- Hybrid components should bridge digital and analog areas, while noise-sensitive components need isolation.

- Digital components should be grouped, and trace lengths minimized; bypass capacitors should be placed near power pins.

Improving BGA Soldering Quality

As products become lighter and thinner, soldering precision for PCBs, especially flexible ones, is crucial. The shrinking component pitches raise control requirements for soldering, emphasizing the board’s flatness during printing.

Flexible and thin PCBs are soft and may not bond securely to the carrier, causing shape distortions. Using silicone gel on the carrier can address this issue but presents challenges:

- Controlling the uniformity of silicone gel thickness is challenging.

- Silicone gel can leave residual buildup, not meeting environmental standards.

- Maintaining silicone gel is difficult, with a short lifespan and high cost.

- Removing silicone gel post-use can be cumbersome.

Introducing a Revolutionary Teflon Double-Sided Adhesive for PCBs

A cutting-edge Teflon double-sided adhesive has recently hit the market, offering a game-changing alternative to the traditional silicone coating method. This innovative adhesive not only meets RoHS requirements but also boasts superior performance benefits. Test results conducted by various PCB manufacturers have revealed that this new adhesive leads to a remarkable enhancement in soldering yield. Interestingly, the more stringent the precision requirements, the greater the improvement in yield.

For any inquiries or further information about PCBs, feel free to reach out to us at info@wellcircuits.com.