Important Considerations When Purchasing a SMT Line

Planning to invest in a Surface Mount Technology (SMT) line involves various crucial factors that need to be addressed. While the engineering aspects may have been taken care of, there are other issues that require attention before finalizing the purchase.

Key Points to Address:

- Location: Ensure the installation site is suitable and meets all requirements for the SMT line.

- Power Upgrade: Verify if the current power supply is adequate for the equipment.

- ESD Floor: Implement Electrostatic Discharge (ESD) precautions to protect sensitive components.

- Business Related Issues: Address any financial or operational considerations that may impact the purchase.

When considering the equipment for the SMT line, components such as the paste mixer, printing machine, pick and place system, oven, and additional accessories like conveyors and feeder carts are essential. While budget constraints may limit automated inspection capabilities initially, manual inspection can suffice temporarily.

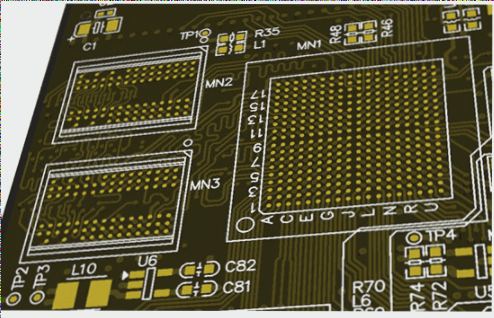

However, understanding the significance of Automated Optical Inspection (AOI), Solder Paste Inspection (SPI), and Automated X-ray Inspection (AXI) is crucial for ensuring product quality.

Key Questions to Consider:

- AOI vs. SPI: Differentiating between AOI and SPI functionalities is essential. Can generic AOI machines perform SPI tasks, or is SPI a specialized function?

- AXI for QFN Packages: While AXI is commonly used for Ball Grid Array (BGA) inspection, it may also be necessary for detecting defects in Quad Flat No-Lead (QFN) packages. Certain defects, such as voiding on ground pads or inconsistent paste depositions, are challenging to identify without AXI.

- Reliable Suppliers: While Chinese companies offer reliable SMT equipment for printing, pick and place, and ovens, identifying reputable suppliers for AOI, SPI, and AXI machines is essential for production efficiency.

Exploring reputable manufacturers for AOI, SPI, and AXI machines can enhance the overall quality control process within the SMT line setup. By addressing these considerations, you can make informed decisions regarding equipment purchases and streamline your production processes effectively.