1 FR-4 is a code name for a fire-resistant material grade, representing a material specification requiring resin materials to self-extinguish after combustion.

2 It is not a material name, but a material grade.

3 Therefore, there are generally many types of FR-4 grade materials used in circuit boards, but most of them are composite materials made of so-called four functional epoxy resin with fillers and glass fibers.

FR-4 epoxy glass cloth laminates are commonly referred to in the industry as FR-4 epoxy glass cloth, insulation board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4, fiberglass board, fiberglass board, FR-4 reinforcement board, FPC reinforcement board, flexible circuit board reinforcement board, FR-4 epoxy resin board, flame-retardant insulation board, FR-4 laminated board, epoxy board, FR-4 optical board, FR-4 fiberglass board, epoxy glass cloth board Epoxy glass cloth laminate, circuit board drilling pad.

Main technical features and applications:

Electrical insulation, stability, good flatness, smooth surface, no pits, thickness tolerance standards, suitable for products with high-performance electronic insulation requirements, such as FPC reinforcement plates, PCB drilling pads, fiberglass mesons, potentiometer carbon film printed fiberglass plates, precision planetary gears (chip grinding), precision testing plates, electrical (electrical) equipment insulation support bar partitions, insulation pads transformer insulation board, motor insulation parts, grinding gears, electronic switch insulation board, etc.

Performance of FR4 material

FR-4 epoxy fiberglass cloth substrate is a type of substrate that uses epoxy resin as the adhesive and electronic-grade fiberglass cloth as the reinforcing material. Its adhesive sheet and thin copper-clad inner core are important substrates for producing multi-layer printed circuit boards.

The mechanical properties, dimensional stability, impact resistance, and moisture resistance of epoxy glass fiber cloth substrate are higher than those of paper substrate. It has excellent electrical performance at high operating temperatures, and its performance is less affected by the environment. In terms of processing technology, it has great advantages over other resin-based fiberglass cloth boards. This type of product is mainly used for double-sided PCBs and requires a large amount of usage.

Characteristics of FR4 material

1. Strong high-temperature resistance: FR4 material has good high-temperature resistance and can withstand temperatures up to 180 ℃. This makes it widely used in electronic devices, such as computer motherboards, power adapters, and so on.

2. Good corrosion resistance: FR4 material has strong corrosion resistance, can resist the erosion of most chemicals, and has a long service life.

3. High mechanical strength: FR4 material has high mechanical strength, which can withstand external impacts and vibrations, and protect the internal circuits of the equipment.

4. Good insulation performance: FR4 material has excellent insulation performance, which can effectively prevent current leakage and electromagnetic interference, ensuring the normal operation of the circuit.

5. Good dimensional stability: FR4 materials have good dimensional stability during the manufacturing process, are not easily deformed, and ensure the accuracy and reliability of the circuit board.

6. Good environmental friendliness: FR4 material is made of environmentally friendly materials, non-toxic and harmless, and will not cause harm to the environment and human body.

The purpose of FR4 material

FR4 material has a wide range of applications, mainly in fields such as electronics, electrical, communication, aerospace, etc. The following are its main uses:

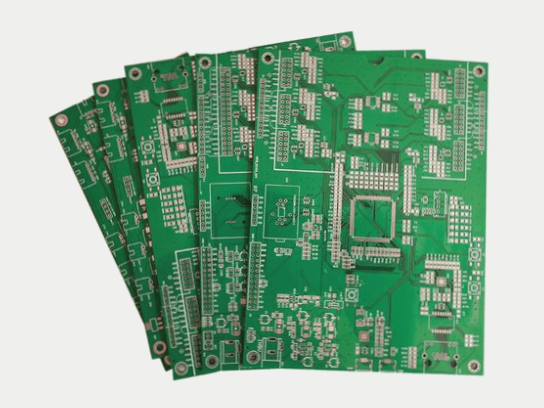

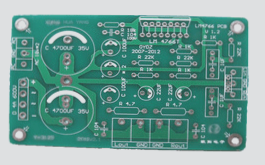

1. Circuit board

In electronic manufacturing, FR4 materials are usually used for the manufacturing of circuit boards. It can be used as a substrate material for circuit boards, ensuring their stability and reliability.

2. Partition and isolation materials

FR4 material has excellent insulation performance and high-temperature stability, so it can be used as a partition and isolation material in power systems. This not only ensures the electrical safety of the equipment but also avoids accidents caused by electrical faults.

3. Mechanical parts

FR4 material can also be used as materials for mechanical parts, such as machine tool partitions, car engine covers, etc. It has excellent mechanical properties and chemical stability and can be applied to different mechanical systems.

FR4 material is one of the most commonly used materials in electronic manufacturing, mainly due to its excellent electrical, mechanical, and chemical stability. In addition, FR4 material also have extremely high insulation and heat resistance, which can withstand high temperatures and high-pressure working environments.

2 It is not a material name, but a material grade.

3 Therefore, there are generally many types of FR-4 grade materials used in circuit boards, but most of them are composite materials made of so-called four functional epoxy resin with fillers and glass fibers.

FR-4 epoxy glass cloth laminates are commonly referred to in the industry as FR-4 epoxy glass cloth, insulation board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4, fiberglass board, fiberglass board, FR-4 reinforcement board, FPC reinforcement board, flexible circuit board reinforcement board, FR-4 epoxy resin board, flame-retardant insulation board, FR-4 laminated board, epoxy board, FR-4 optical board, FR-4 fiberglass board, epoxy glass cloth board Epoxy glass cloth laminate, circuit board drilling pad.

Main technical features and applications:

Electrical insulation, stability, good flatness, smooth surface, no pits, thickness tolerance standards, suitable for products with high-performance electronic insulation requirements, such as FPC reinforcement plates, PCB drilling pads, fiberglass mesons, potentiometer carbon film printed fiberglass plates, precision planetary gears (chip grinding), precision testing plates, electrical (electrical) equipment insulation support bar partitions, insulation pads transformer insulation board, motor insulation parts, grinding gears, electronic switch insulation board, etc.

Performance of FR4 material

FR-4 epoxy fiberglass cloth substrate is a type of substrate that uses epoxy resin as the adhesive and electronic-grade fiberglass cloth as the reinforcing material. Its adhesive sheet and thin copper-clad inner core are important substrates for producing multi-layer printed circuit boards.

The mechanical properties, dimensional stability, impact resistance, and moisture resistance of epoxy glass fiber cloth substrate are higher than those of paper substrate. It has excellent electrical performance at high operating temperatures, and its performance is less affected by the environment. In terms of processing technology, it has great advantages over other resin-based fiberglass cloth boards. This type of product is mainly used for double-sided PCBs and requires a large amount of usage.

Characteristics of FR4 material

1. Strong high-temperature resistance: FR4 material has good high-temperature resistance and can withstand temperatures up to 180 ℃. This makes it widely used in electronic devices, such as computer motherboards, power adapters, and so on.

2. Good corrosion resistance: FR4 material has strong corrosion resistance, can resist the erosion of most chemicals, and has a long service life.

3. High mechanical strength: FR4 material has high mechanical strength, which can withstand external impacts and vibrations, and protect the internal circuits of the equipment.

4. Good insulation performance: FR4 material has excellent insulation performance, which can effectively prevent current leakage and electromagnetic interference, ensuring the normal operation of the circuit.

5. Good dimensional stability: FR4 materials have good dimensional stability during the manufacturing process, are not easily deformed, and ensure the accuracy and reliability of the circuit board.

6. Good environmental friendliness: FR4 material is made of environmentally friendly materials, non-toxic and harmless, and will not cause harm to the environment and human body.

The purpose of FR4 material

FR4 material has a wide range of applications, mainly in fields such as electronics, electrical, communication, aerospace, etc. The following are its main uses:

1. Circuit board

In electronic manufacturing, FR4 materials are usually used for the manufacturing of circuit boards. It can be used as a substrate material for circuit boards, ensuring their stability and reliability.

2. Partition and isolation materials

FR4 material has excellent insulation performance and high-temperature stability, so it can be used as a partition and isolation material in power systems. This not only ensures the electrical safety of the equipment but also avoids accidents caused by electrical faults.

3. Mechanical parts

FR4 material can also be used as materials for mechanical parts, such as machine tool partitions, car engine covers, etc. It has excellent mechanical properties and chemical stability and can be applied to different mechanical systems.

FR4 material is one of the most commonly used materials in electronic manufacturing, mainly due to its excellent electrical, mechanical, and chemical stability. In addition, FR4 material also have extremely high insulation and heat resistance, which can withstand high temperatures and high-pressure working environments.