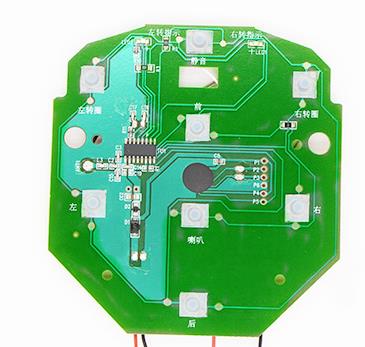

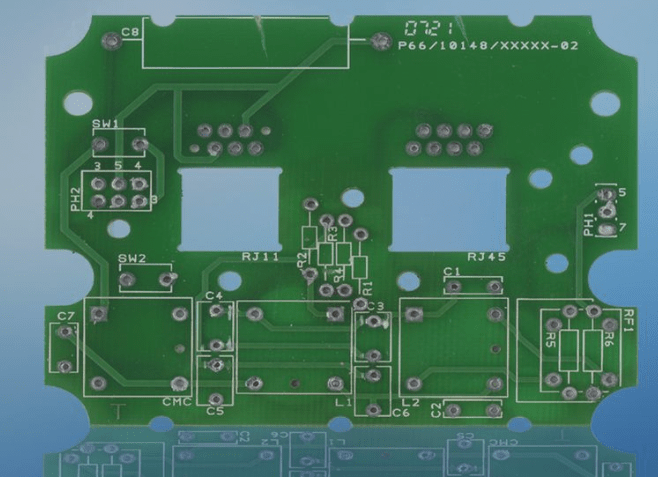

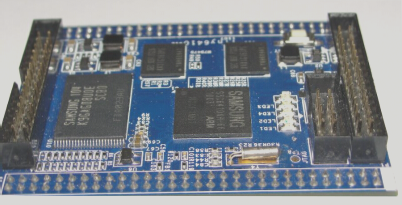

PCBA Circuit Board Processing Challenges and Solutions

PCBA circuit board processing is a critical step in electronic equipment design and production. The quality of the PCBA circuit board directly influences the functionality and overall quality of the devices. To ensure superior products, high-quality PCBA circuit board support is essential. However, various challenges can arise during PCBA circuit board processing. Let’s focus on one solution today: addressing the causes of throwing and their corresponding solutions.

Reason 1: Nozzle Issues

Issues with the nozzle, such as deformation, blockage, or damage due to insufficient air pressure or leakage, can result in inadequate suction, incorrect retrieval, and identification failures, leading to PCBA throwing.

Countermeasures: Clean and replace the suction nozzle.

Reason 2: Feeder Issues

Feeder problems, such as incorrect setup or inefficient feeding mechanisms, can lead to throwing.

Countermeasures: Recalibrate the feeder, clean the equipment, and adjust or replace the feeder.

Reason 3: Recognition System Problems

Issues with the recognition system, like poor visibility or improper light source selection, can cause throwing.

Countermeasures: Clean the system surfaces, adjust light source settings, and replace faulty components.

Reason 4: Positional Inaccuracies

Positioning errors during pickup can result in misalignment and material rejection.

Countermeasures: Adjust retrieval position and height settings.

Reason 5: Vacuum-Related Issues

Vacuum problems, such as insufficient pressure or blockages, can lead to material drops during transport.

Countermeasures: Adjust air pressure, clear vacuum lines, and repair leaks.

Reason 6: Programming Errors

Errors in the placement machine’s program settings can cause recognition failures.

Countermeasures: Modify component parameters in the program.

Reason 7: Incoming Material Problems

Issues with incoming materials, like non-standard products, can lead to rejection.

Countermeasures: Inspect incoming materials thoroughly and communicate with suppliers.

Reason 8: Feeder Troubles

Feeder problems, such as poor performance or damage, can result in faulty retrieval and feeder damage.

Countermeasures: Correct feeders, clean platforms, and replace damaged parts.

Static electricity can also contribute to PCBA rejection, emphasizing the importance of proper grounding and anti-static measures in the production area. While occasional rejection is normal, a high rejection rate can impact efficiency and costs. It’s crucial to address rejection issues promptly to improve production efficiency. Consulting on-site personnel and analyzing the identified reasons can help identify root causes effectively.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย