Reasons for PCB Circuit Board Failure:

According to relevant data reports, up to 78% of hardware failures are caused by poor PCB soldering processing.

In the case of hardware failure, engineers are willing to spend a lot of time and energy on debugging and analyzing the prototype, which delays the progress of the project. If they can’t identify the reason for the failure, they tend to attribute it to the design of the software and hardware circuits. When performing hardware debugging, engineers often consider numerous high-level potential causes, but they are reluctant to question the most obvious and common mistakes:

Case 1: A large number of decoupling capacitors are densely distributed next to the CPU power supply. Due to excess solder during the PCB soldering process, a certain electrical PCB capacitor becomes short-circuited. This forces hardware engineers to painstakingly troubleshoot the short-circuit issue, consuming a significant amount of time.

Case 2: In the DDR high-speed signal section, a particular signal suffers from virtual welding, causing the system to appear functional when transmitting small data volumes but encountering errors during burst operations such as operating system loading and high-definition movie playback. This issue is often wrongly attributed to software problems, leading software engineers to search for solutions in the code without success.

Case 3: In the high-speed signal interface connector, a false soldering of a certain signal leads to the system functioning at a reduced capacity due to PCB welding processing.

Case 4: Poor soldering in the inductor part results in the failure of the PWM dimming function of the LED. The PCB soldering process engineer spends considerable time determining whether the issue is a software or hardware problem.

Case 5: Improper time and temperature control during soldering cause plastic parts within connectors like LCD and USB to melt and deform, leading to the accidental disconnection of a signal, resulting in no LCD display and USB communication. This is often mistakenly perceived as a software driver problem.

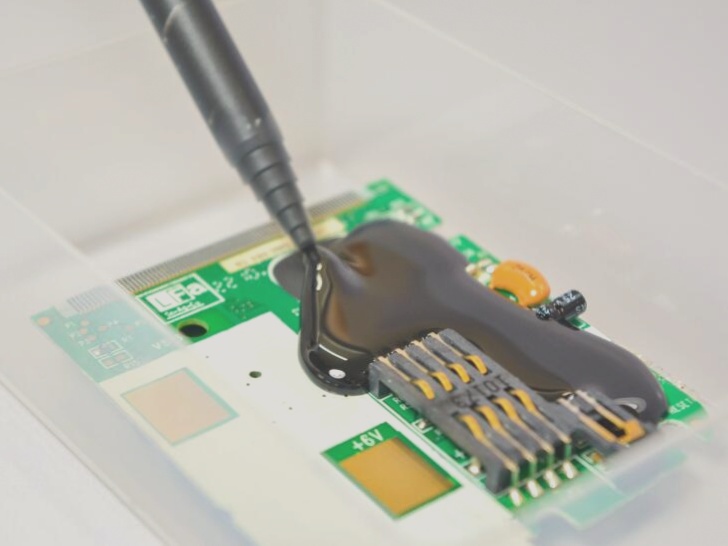

While these problems may seem simple, they involve numerous soldering details and steps that are interconnected, with any error potentially triggering issues. Therefore, it is advisable for engineers to first assess the soldering quality of their prototype during the hardware debugging process.

After addressing the aforementioned “simple and obvious” issues related to PCB soldering, engineers can then focus on resolving the more “advanced” problems. This strategic approach is the wise choice.

According to relevant data reports, up to 78% of hardware failures are caused by poor PCB soldering processing.

In the case of hardware failure, engineers are willing to spend a lot of time and energy on debugging and analyzing the prototype, which delays the progress of the project. If they can’t identify the reason for the failure, they tend to attribute it to the design of the software and hardware circuits. When performing hardware debugging, engineers often consider numerous high-level potential causes, but they are reluctant to question the most obvious and common mistakes:

Case 1: A large number of decoupling capacitors are densely distributed next to the CPU power supply. Due to excess solder during the PCB soldering process, a certain electrical PCB capacitor becomes short-circuited. This forces hardware engineers to painstakingly troubleshoot the short-circuit issue, consuming a significant amount of time.

Case 2: In the DDR high-speed signal section, a particular signal suffers from virtual welding, causing the system to appear functional when transmitting small data volumes but encountering errors during burst operations such as operating system loading and high-definition movie playback. This issue is often wrongly attributed to software problems, leading software engineers to search for solutions in the code without success.

Case 3: In the high-speed signal interface connector, a false soldering of a certain signal leads to the system functioning at a reduced capacity due to PCB welding processing.

Case 4: Poor soldering in the inductor part results in the failure of the PWM dimming function of the LED. The PCB soldering process engineer spends considerable time determining whether the issue is a software or hardware problem.

Case 5: Improper time and temperature control during soldering cause plastic parts within connectors like LCD and USB to melt and deform, leading to the accidental disconnection of a signal, resulting in no LCD display and USB communication. This is often mistakenly perceived as a software driver problem.

While these problems may seem simple, they involve numerous soldering details and steps that are interconnected, with any error potentially triggering issues. Therefore, it is advisable for engineers to first assess the soldering quality of their prototype during the hardware debugging process.

After addressing the aforementioned “simple and obvious” issues related to PCB soldering, engineers can then focus on resolving the more “advanced” problems. This strategic approach is the wise choice.