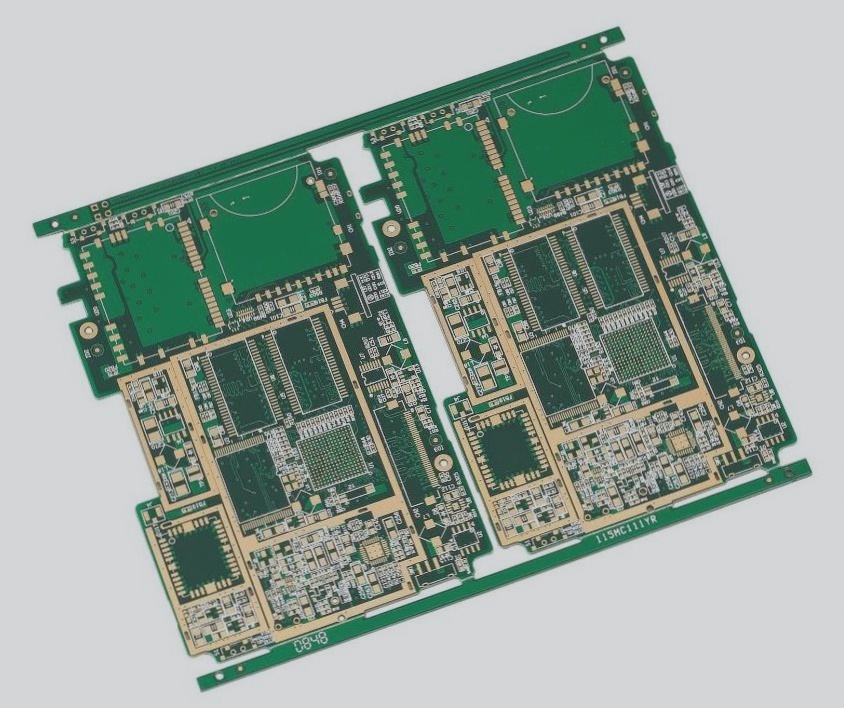

1. The problems that occur in the PCB manufacturing process are often quite perplexing, and it is the responsibility of the process engineer to conduct a thorough investigation and implement effective solutions. Therefore, the primary aim of initiating this discussion topic is to delve into the various factors within the equipment domain, encompassing people, machinery, materials, and environmental conditions that may give rise to issues. We welcome everyone to contribute and share their insights.

2. The utilization of pre-treatment equipment in processes such as inner layer pre-treatment lines, copper electroplating pre-treatment lines, D/F, and solder mask application, among others, is crucial.

3. Let’s take the example of a hard board PCB solder mask pre-treatment line (specific procedures may vary among manufacturers): double groups of brushing->water rinsing->pickling->water rinsing->cold air knife->drying section->UV exposure->unloading.

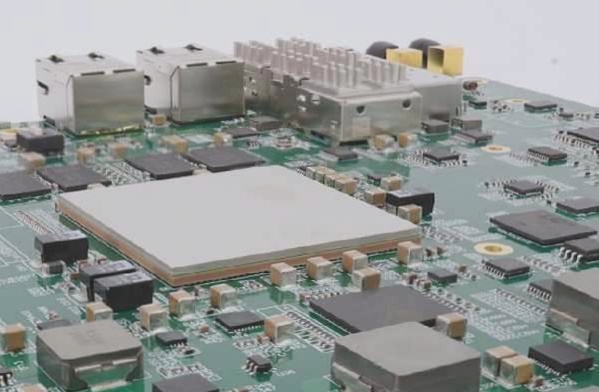

4. Typically, gold steel brushes with brush wheels of #600 and #800 are employed, impacting the board surface roughness and hence the adhesion of ink and copper surface. Extended use of the brush wheel may result in uneven wear, leading to issues like “dog boning,” causing surface roughness irregularities, line distortion, and color discrepancy between the copper surface and ink post-printing. Hence, it is essential to conduct a comprehensive brushmark test (or water break test in the case of D/F), with brush mark widths ranging from 0.8 to 1.2mm, varying based on the product. Regular adjustment of the brush wheel level post-brush replacement is necessary, along with periodic lubrication. Inadequate water boiling during brushing or insufficient spray pressure to generate a fan-shaped angle may result in copper powder formation, potentially causing micro-short circuits during final product testing or failure in high voltage tests.

An additional prevalent issue in pre-treatment is board surface oxidation, leading to surface bubbling or cavities post-H/A.

1. Misplacement of the solid water-retaining roller in pre-treatment can result in excessive acid transfer to the rinsing section. Insufficient washing tanks in subsequent sections or inadequate water injection may lead to acid residue on the board surface.

2. Poor water quality in the rinsing section or impurities present may result in foreign matter adhering to the copper surface.

3. Dry or saturated water-absorbing rollers might fail to effectively remove water from the product, resulting in excessive water residue on the board surface and within holes, hindering proper air knife functioning. Vacuoles formed during this process are often tear-shaped at via hole edges.

4. Stacking and sealing boards while still at residual temperatures post-material discharge can lead to copper surface oxidation.

To monitor water pH, a PH detector can be utilized, while infrared rays can measure board surface residual temperatures. Specific wet conditions must be defined, ideally with two sets of suction wheels for alternate use. The air knife angle must be verified daily before operation, and it’s crucial to check for any detachment or damage in the drying section’s air ducts.

2. The utilization of pre-treatment equipment in processes such as inner layer pre-treatment lines, copper electroplating pre-treatment lines, D/F, and solder mask application, among others, is crucial.

3. Let’s take the example of a hard board PCB solder mask pre-treatment line (specific procedures may vary among manufacturers): double groups of brushing->water rinsing->pickling->water rinsing->cold air knife->drying section->UV exposure->unloading.

4. Typically, gold steel brushes with brush wheels of #600 and #800 are employed, impacting the board surface roughness and hence the adhesion of ink and copper surface. Extended use of the brush wheel may result in uneven wear, leading to issues like “dog boning,” causing surface roughness irregularities, line distortion, and color discrepancy between the copper surface and ink post-printing. Hence, it is essential to conduct a comprehensive brushmark test (or water break test in the case of D/F), with brush mark widths ranging from 0.8 to 1.2mm, varying based on the product. Regular adjustment of the brush wheel level post-brush replacement is necessary, along with periodic lubrication. Inadequate water boiling during brushing or insufficient spray pressure to generate a fan-shaped angle may result in copper powder formation, potentially causing micro-short circuits during final product testing or failure in high voltage tests.

An additional prevalent issue in pre-treatment is board surface oxidation, leading to surface bubbling or cavities post-H/A.

1. Misplacement of the solid water-retaining roller in pre-treatment can result in excessive acid transfer to the rinsing section. Insufficient washing tanks in subsequent sections or inadequate water injection may lead to acid residue on the board surface.

2. Poor water quality in the rinsing section or impurities present may result in foreign matter adhering to the copper surface.

3. Dry or saturated water-absorbing rollers might fail to effectively remove water from the product, resulting in excessive water residue on the board surface and within holes, hindering proper air knife functioning. Vacuoles formed during this process are often tear-shaped at via hole edges.

4. Stacking and sealing boards while still at residual temperatures post-material discharge can lead to copper surface oxidation.

To monitor water pH, a PH detector can be utilized, while infrared rays can measure board surface residual temperatures. Specific wet conditions must be defined, ideally with two sets of suction wheels for alternate use. The air knife angle must be verified daily before operation, and it’s crucial to check for any detachment or damage in the drying section’s air ducts.