PCB Reflow Oven Failure: Troubleshooting Guide

Dear PCB enthusiasts,

If you’ve encountered issues with your PCBs failing in the reflow oven, you’re not alone. Many factors can contribute to this problem, from design flaws to oven settings. Let’s delve into some common causes and solutions.

Root Cause Analysis:

- Failure Symptom: Localized overheating near the back of the oven, resulting in burnt board innards.

- Possible Causes:

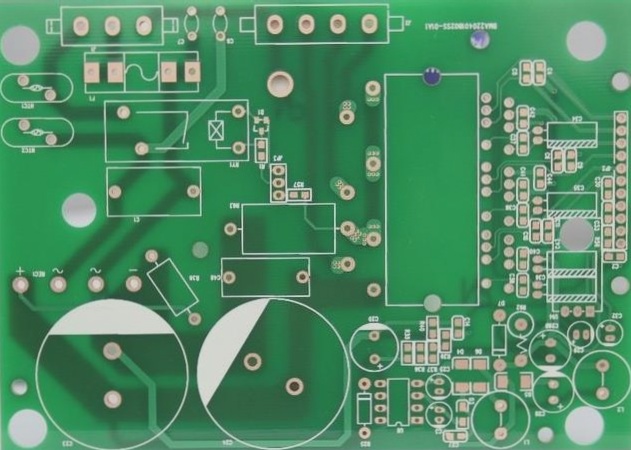

- Missing ground plane on the board.

- Poor heat distribution in the oven.

- Potential exposed heating element.

Solutions to Consider:

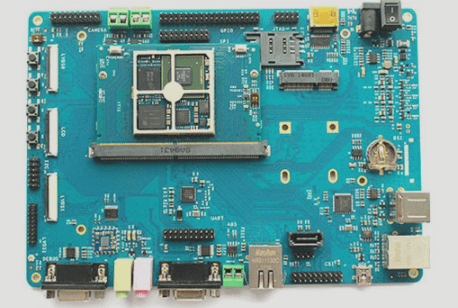

- Introduce a ground plane on both sides of the PCB to distribute heat evenly.

- Verify oven temperature accuracy and check for any exposed heating elements.

- Optimize reflow oven settings to ensure a consistent temperature profile.

By addressing these factors, you can enhance the reliability of your PCB assembly process and minimize the risk of failures in the reflow oven. Don’t hesitate to experiment with different approaches and seek professional advice if needed.

Thank you for your attention to this matter.