Challenges and Solutions in High-Density Interconnect (HDI) PCB Manufacturing

Introduction

High-Density Interconnect (HDI) PCBs have transformed the electronics industry, enabling the creation of compact and high-performance devices. Despite their numerous advantages, the manufacturing of HDI PCBs poses unique challenges that must be addressed to ensure reliability and functionality.

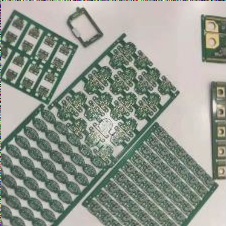

1. Microvias: Precision in Design and Manufacturing

Microvias are tiny holes that connect different layers of the PCB, offering design flexibility but also introducing complexities in manufacturing.

Challenge:

- Drilling and plating microvias require precise control to avoid defects like fractures or blockages.

Solution:

- Advanced laser drilling technology provides enhanced precision, reducing the risk of damage and ensuring accurate microvias.

- Rigorous inspection methods throughout manufacturing maintain microvia integrity, preventing defects.

2. Material Selection: Balancing Performance Requirements

Choosing the right materials for HDI PCBs is critical for meeting electrical and thermal performance needs.

Challenge:

- Material selection must fulfill both electrical and thermal management requirements to avoid signal integrity issues and reduced lifespan.

Solution:

- Close collaboration with material suppliers helps in selecting appropriate substrates tailored for HDI PCBs.

- Extensive testing of materials before assembly ensures they meet necessary specifications, reducing performance risks.

Additional Challenges and Solutions

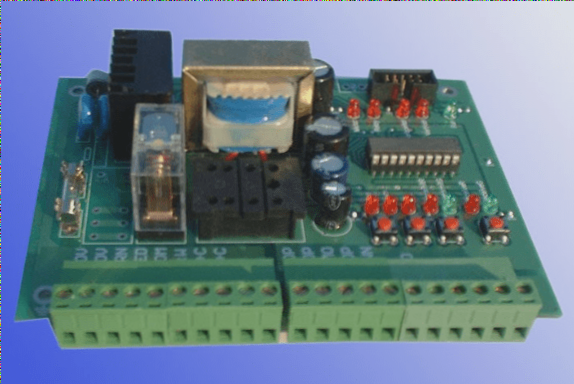

1. Component Placement and Soldering Complexity

The dense packing of components in HDI PCBs presents challenges in accurate placement and solder joint quality.

Challenge:

- Limited space complicates component placement and solder joint quality, leading to issues like bridging or cold joints.

Solution:

- Automated pick-and-place machines improve placement accuracy, while advanced soldering techniques enhance joint quality.

2. Heat Dissipation Management

Efficient heat dissipation is crucial for preventing thermal failures and maintaining performance in powerful electronic devices.

Challenge:

- The high component density in HDI PCBs results in increased heat generation, risking thermal failure and performance degradation.

Addressing these challenges through advanced technologies and close collaborations is essential for producing reliable and high-performance HDI PCBs that meet the demands of modern electronic devices.

Solving Challenges in HDI PCB Design and Assembly

- Thermal Management: Designing HDI PCBs with thermal management in mind is crucial for efficient heat dissipation. Strategies like thermal vias, heat sinks, and high thermal conductivity materials help maintain optimal performance.

- Advanced Testing Methods: Traditional testing may not effectively identify issues in complex HDI PCBs. Implementing Automated Optical Inspection (AOI) and X-ray inspection can detect defects early, ensuring product reliability.

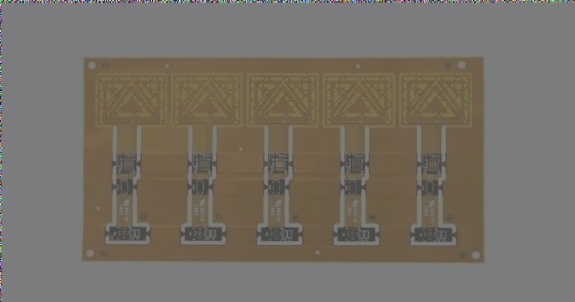

4-Layer Flex Circuit with HDI

The complexity of HDI PCB assembly requires stringent process control to ensure high-quality production. Challenges such as manufacturing process variability can impact product performance. Implementing robust process controls, quality assurance protocols, and automated inspection tools can mitigate these issues.

Key Considerations for HDI PCB Assembly

Assembling HDI PCBs involves critical factors like microvia technology, material selection, soldering methods, thermal management, and testing protocols. Each element is essential for ensuring product reliability and functionality.

Advanced Techniques for HDI PCB Assembly

Continuous innovation in assembly techniques is vital for staying competitive in the electronics market. Addressing challenges like high-density interconnects, multi-layer structures, and thermal management enhances the performance of HDI PCBs in compact devices.

Conclusion

By integrating advanced technologies and meticulous processes in HDI PCB design and assembly, manufacturers can overcome challenges, improve product quality, and meet the demands of the evolving electronics industry.

The Importance of HDI PCB Assembly in the Era of Advanced Electronics

With the increasing demand for smaller and more powerful electronic devices, the significance of overcoming challenges related to HDI PCB assembly cannot be overstated. Manufacturers striving to remain competitive must prioritize process control, material selection, and the adoption of advanced assembly techniques.

Key Points to Consider:

- Process Control: Implementing stringent quality control measures is essential to ensure the successful assembly of HDI PCBs.

- Material Selection: Choosing the right materials is crucial for addressing challenges such as microvia technology and thermal management.

- Advanced Assembly Techniques: Embracing cutting-edge assembly methods is vital to enhancing the reliability and performance of HDI PCBs.

By continuously innovating and fostering collaboration within the industry, HDI PCBs will continue to play a pivotal role in the development of next-generation electronic devices. These advanced PCBs offer the reliability and performance needed to support the demands of modern electronics design and manufacturing.

Summary:

HDI PCB assembly is a sophisticated process that demands strict quality control and the use of innovative techniques to tackle challenges like microvia technology, material selection, and thermal management. Manufacturers can elevate the reliability and performance of HDI PCBs by enforcing process controls, leveraging advanced materials, and embracing state-of-the-art assembly methods. As the market clamors for smaller and more efficient electronic devices, surmounting these obstacles will be imperative for sustaining a competitive advantage in the industry.