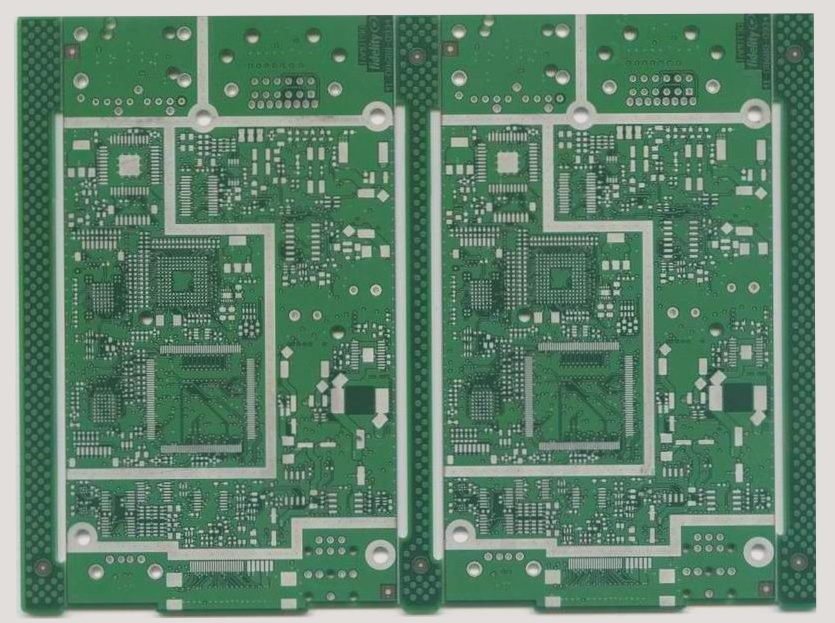

Challenges and Considerations in Multi-Layer PCB Board Production

- Multi-layer PCB boards, consisting of more than 10 layers, require advanced processing and production techniques, offering higher product stability and wider applications.

- Most multi-layer PCB board manufacturers in the market are Sino-foreign joint ventures or foreign companies, showcasing the high level of craftsmanship and substantial initial investment required.

- Key Points in Production:

- Alignment Precision: The more layers, the stricter the alignment requirements, typically controlled within ±75μm tolerance.

- Material Differences: Thicker surfaces increase inner line layout complexity, with thin inner core plates prone to exposure issues.

- Pressing Process: Delamination and skateboarding risks necessitate careful consideration of material properties during design.

- Drilling Challenges: Special materials increase drilling difficulty, testing drilling technology proficiency and requiring extra attention to prevent breakage and inclined drilling.

Market Prospects for Multi-Layer PCB Boards

Despite the challenges, the market prospects for multi-layer PCB boards remain promising due to their wide range of applications and high product stability.