Surface Mount Technology (SMT) Prototype Production Challenges

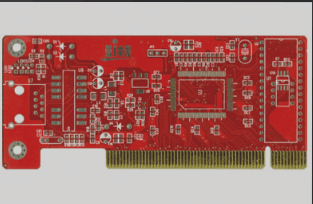

Surface Mount Technology (SMT) has transformed electronic component assembly on printed circuit boards (PCBs). While SMT offers benefits like higher component density and improved reliability, the prototype production phase comes with unique challenges. Let’s delve into the difficulties encountered during SMT prototype production and explore strategies to overcome them.

1. Design Complexity

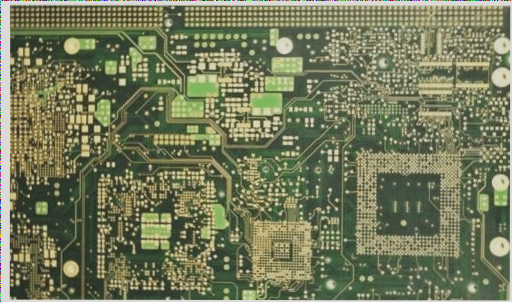

Modern electronic designs are intricate, with high-density layouts and closely packed components. Signal integrity issues, thermal concerns, and short circuits can arise. Engineers must use advanced design tools and follow best practices in PCB layout, including thorough simulations and design rule checks, to identify and address potential problems early.

2. Component Variability

The increasing variety of component sizes and types complicates the assembly process. Careful selection of compatible components, precise handling, and placement techniques are essential to minimize damage and ensure accurate assembly.

3. Soldering Quality Control

The high volume of soldering in SMT assembly can lead to defects like cold joints or insufficient soldering. Advanced soldering techniques, precise temperature control, and automated optical inspection systems can enhance defect detection and improve overall production efficiency.

4. Tight Timelines

Quick turnaround times for prototypes can result in rushed design processes and manufacturing steps. Planning ample time for design verification, component sourcing, and assembly, along with close communication between teams, is crucial to prevent errors and delays.

5. Cost Constraints and Small Batch Production

PCB prototype production in small batches may increase per-unit costs and limit access to advanced manufacturing equipment. Collaboration with manufacturers offering flexible small-batch services and exploring alternative manufacturing options can help maintain quality while managing costs.

Conclusion

Addressing challenges in SMT prototype production requires a combination of advanced tools, precise techniques, thorough planning, and effective communication. By overcoming design complexity, component variability, soldering defects, tight timelines, and cost constraints, engineers can achieve successful SMT prototype production, setting the stage for high-quality end products.

The Challenges of Component Sourcing in PCB Design

The rapid advancement of technology often leads to components becoming obsolete or hard to find, posing challenges in prototype production. Sudden changes in component availability can cause delays and increased costs. To mitigate risks, thorough market research and relationships with multiple suppliers are crucial. Maintaining an up-to-date Bill of Materials (BOM) with alternative components offers flexibility in parts sourcing.

Ensuring Accurate Solder Paste Application in SMT Assembly

Accurate application of solder paste is vital for successful Surface-Mount Technology (SMT) assembly. Inconsistent paste application can result in defects like insufficient solder or tombstoning. Achieving the correct stencil thickness and precise alignment during printing are essential. Regular maintenance and calibration of solder paste printers improve accuracy and reduce defects.

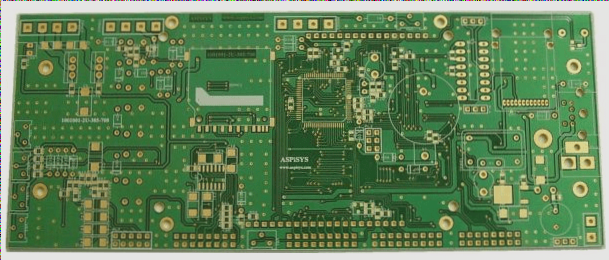

Precision Component Placement for Effective SMT Production

Precision in component placement is crucial for SMT production. Small variations in alignment can cause significant assembly issues, especially in high-density layouts. Advanced machine vision systems can enhance placement precision by verifying component placement in real-time. Investing in high-quality pick-and-place equipment improves placement reliability and overall assembly quality.

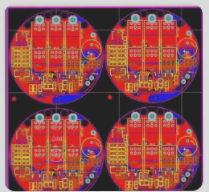

Reflow Soldering and Temperature Profile Optimization

Reflow soldering plays a vital role in SMT production, where achieving the correct temperature profile is crucial for successful soldering. Proper temperature control throughout the reflow process, with gradual transitions between phases, is essential for reliable solder joints. Regular monitoring and adjustments of reflow oven settings maintain consistency and ensure high-quality assemblies.

Quality Control in SMT Prototype Production

Quality control is essential in SMT prototype production to reduce time and costs. Automated Optical Inspection (AOI) systems detect surface-level defects, while X-ray imaging may be needed for hidden solder joints or internal component issues. A comprehensive quality control strategy involving functional and visual inspections ensures high-quality prototypes by addressing defects early in the process.

Striking a Balance Between Speed and Accuracy in Rapid Prototyping

The Importance of Agile Methodologies in Rapid Prototyping

In today’s dynamic market, the need for rapid prototyping is on the rise as companies aim to shorten development cycles while upholding product quality standards. However, the pressure to deliver quickly can result in errors if proper protocols are not followed. To strike a balance between speed and precision, organizations should consider embracing agile methodologies. Agile approaches allow for iterative testing and design adjustments during the prototyping phase, promoting continuous improvement and enabling teams to swiftly respond to feedback. By integrating agile principles into their development processes, companies can meet tight deadlines without compromising prototype quality.

Enhancing SMT Prototype Production Efficiency

SMT prototype production poses various challenges, from intricate design complexities to quality control issues. To address these challenges effectively, manufacturers must adopt a holistic approach.

1. Design and Component Selection

Managing design complexity and selecting the right components are key challenges in SMT prototype production. Collaboration between design engineers and component suppliers early in the process is crucial to ensure component compatibility and availability.

2. Solder Paste Application

Precise solder paste application is critical for reliable component-to-PCB connections. Utilizing advanced equipment like automated solder paste printers with precise control can minimize risks of solder bridging or poor joints.

3. Quality Control and Inspection

Consistent quality is essential throughout the production process. Implementing stringent quality control measures, such as automated optical inspection (AOI) systems and X-ray inspection, helps detect defects early, ensuring high-quality prototypes.

4. Investment in Advanced Technologies

Investing in cutting-edge technologies like advanced pick-and-place machines and automated soldering systems can enhance precision and production speed, critical for meeting tight deadlines in prototype development.

5. Best Practices and Proactive Measures

Proactively addressing challenges through structured processes is crucial. Practices like design reviews, production parameter monitoring, and iterative testing help identify issues early, enabling manufacturers to enhance their processes and meet market demands effectively.

Conclusion

While SMT prototype production presents challenges, manufacturers can overcome them through careful planning, technology investments, and adherence to best practices. By addressing design complexities, component selection, solder paste application, and quality control, manufacturers can streamline their production processes, reduce time-to-market, and deliver superior products. Embracing continuous improvement and learning from each iteration strengthens manufacturers’ ability to succeed in the competitive electronics industry.

Challenges in SMT Prototype Production

Producing SMT prototypes comes with various challenges, ranging from intricate design elements to ensuring quality control. Manufacturers face hurdles that can impact the efficiency and effectiveness of the production process.

Investing in Technology

One way to tackle these challenges is by investing in cutting-edge technology. By leveraging the latest tools and equipment, manufacturers can enhance precision, increase efficiency, and improve overall output quality.

Adopting Best Practices

Another crucial aspect is the adoption of best practices in SMT prototype production. Following industry standards and proven methodologies can help streamline operations, minimize errors, and optimize the workflow.

Proactively Addressing Issues

It’s essential for manufacturers to proactively identify and address potential issues during the production process. By implementing preventive measures and troubleshooting techniques, they can mitigate risks and ensure smooth operations.

Continuous Improvement

The key to success in SMT prototype production lies in continuous improvement. By constantly seeking ways to enhance quality and speed, manufacturers can deliver superior products and reduce time-to-market, gaining a competitive edge in the industry.