Teflon PCB: The Ultimate Solution for High-End Electronic Products

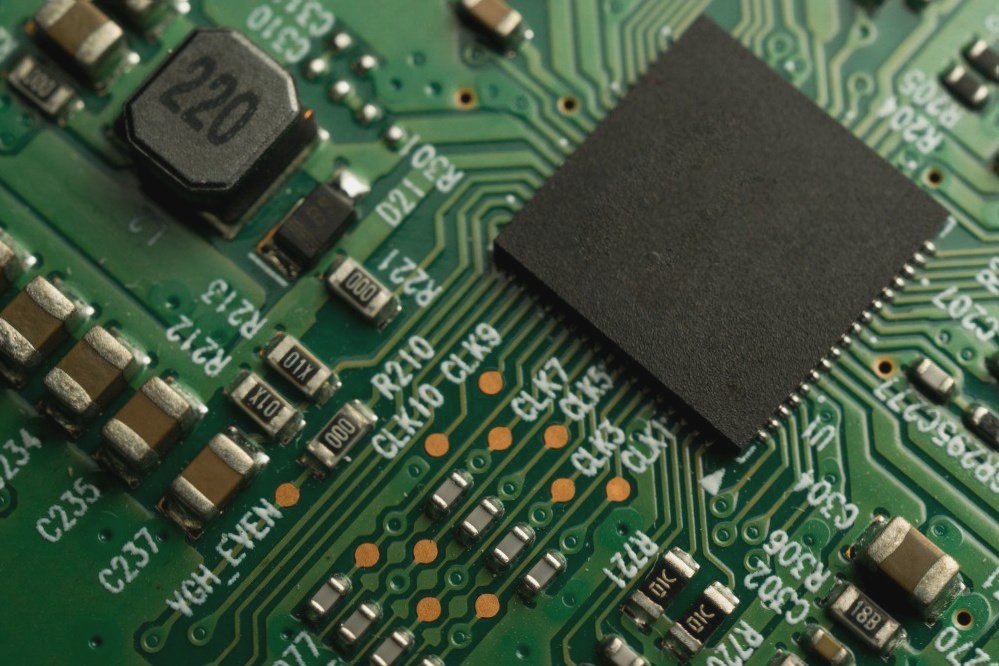

Teflon PCB, also known as polytetrafluoroethylene (PTFE), is widely recognized for its exceptional properties such as resistance to acids, alkalis, and organic solvents, high temperature resistance, and low friction coefficient. It is commonly used for coating water pipes and in PCB prototyping for high-end electronic products.

Key Features of Teflon PCB:

- Material Selection: Teflon PCB samples are produced using materials like Wangling F4B, Rogers 5 series, and Rogers 3 series, offering unique advantages for flexible PCB prototyping.

- Function Test: All Teflon PCB samples undergo rigorous functional testing to ensure optimal performance.

- Temperature Resistance: Teflon PCBs can withstand temperatures ranging from -454 to 600 °F (-270 to 315 °C), making them ideal for military and aerospace applications.

- High Dielectric Strength: With high dielectric strength, Teflon PCBs act as effective insulators, safeguarding equipment from electrical breakdowns.

- Durability: PTFE PCBs are highly durable, resistant to oxidation, UV damage, embrittlement, and discoloration, providing a long-lasting and cost-effective solution.

- Mechanical Rigidity: Teflon PCBs offer mechanical stability and good thermal conductivity, perfect for applications requiring robust mechanical performance.

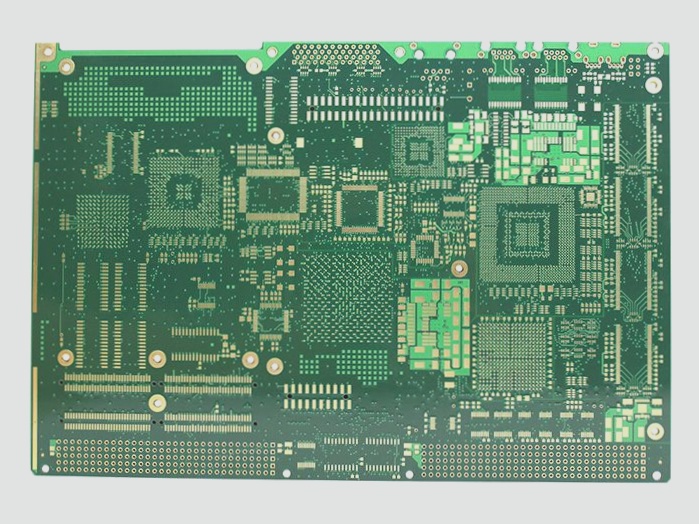

Additional Advantages of Teflon PCB:

- Temperature Resistance: Operational temperature range of 200~260 ℃.

- Low Temperature Resistance: Remains soft at -100 ℃.

- Corrosion Resistance: Resistant to aqua regia and all organic solvents.

- Weather Resistance: Exhibits excellent aging resistance, surpassing other plastics.

- High Lubrication: Minimal friction coefficient (0.04) among plastics.

- Non-Stick Properties: Prevents adherence to any substance with the lowest surface tension among solid materials.

- Physiological Inertia: Acts as an ideal Class C insulating material with outstanding electrical performance, capable of blocking 1500V high voltage with a thick layer of newspaper.

In conclusion, Teflon PCBs offer a comprehensive range of benefits including high temperature and corrosion resistance, non-stick properties, self-lubrication, excellent dielectric performance, and low friction coefficient. These features make Teflon PCBs ideal for high-frequency boards used in radar, high-frequency communication equipment, wireless appliances, and other specialized fields.