Introduction to PCB Assembly Methods

When it comes to assembling printed circuit boards (PCBs), there are two primary methods: Surface-Mount Technology (SMT) and Through-Hole Technology (THT). Each method has its unique set of advantages and disadvantages, and selecting the right one depends on the specific requirements of your project.

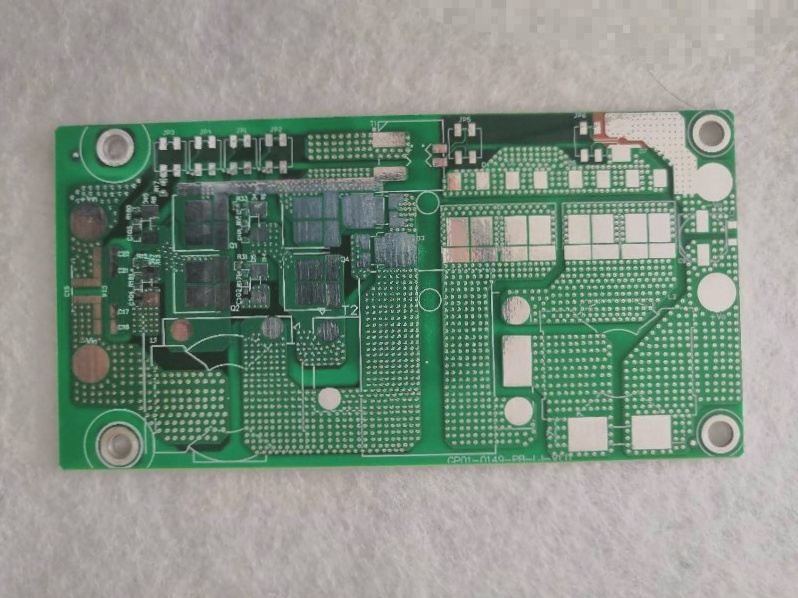

Surface-Mount Technology (SMT)

SMT involves placing electronic components directly onto the surface of the PCB. The components are held in place using solder paste, which is then heated to create a permanent bond. This method is often faster and more automated than THT, making it particularly suited for high-volume production. SMT components are typically smaller, lighter, and more compact than their THT counterparts, allowing for higher component density and saving valuable space on the PCB. As a result, SMT is the preferred choice for most modern electronics, especially for small consumer devices, smartphones, and computers.

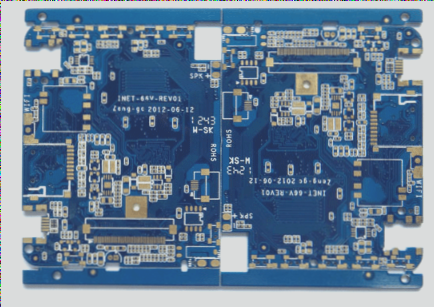

Through-Hole Technology (THT)

THT involves inserting component leads through holes drilled in the PCB and soldering them to pads on the opposite side. This method is ideal for larger, heavier components that may not be suitable for surface-mounting. THT is often used for components that require greater mechanical strength, such as connectors, large capacitors, and power components. Additionally, THT is commonly chosen for prototyping and small production runs because it allows for easier hand-soldering compared to SMT, which typically requires specialized equipment.

Comparison of SMT and THT

While both SMT and THT have their respective advantages, the choice between the two largely depends on factors like component size, production volume, and mechanical requirements. SMT excels in high-density, automated environments with smaller components, whereas THT is better suited for larger, more robust components and situations that require manual soldering.

Choosing the Right PCB Assembly Method

Choosing the right PCB assembly method is a critical decision that directly influences the cost, quality, and overall performance of your product. The best PCB assembly method for your project will depend on several factors, including:

- The type of components you are using

- The size and complexity of your PCB

- The production volume

- Your budget

Conclusion

Selecting the appropriate PCB assembly method requires a balanced consideration of your project’s specific requirements, including component type, PCB size and complexity, production volume, and budget. Understanding these factors will help you make an informed decision that aligns with both your technical needs and cost constraints.

Factors to Consider When Selecting a PCB Assembly Method

- Several factors must be carefully considered when selecting the most suitable method, including the complexity of the design, production volume, and required precision.

- For low-volume or prototype production, methods such as hand soldering or small-scale automated assembly may be more cost-effective. However, for high-volume production, automated methods like Surface Mount Technology (SMT) or Through-Hole Technology (THT) offer greater efficiency and consistency.

- Additionally, it’s essential to consider the material compatibility, the type of components, and the desired end-use environment of the product. These elements can significantly affect the choice of assembly method and the final performance of the PCB.

- Furthermore, ensuring that the assembly method aligns with your supply chain capabilities, manufacturing lead times, and quality control standards is crucial to the success of the project.

Latest Trends in PCB Assembly

One of the latest trends in PCB assembly is the increasing adoption of advanced robotics and artificial intelligence in the manufacturing process. These technologies help improve efficiency, accuracy, and consistency in PCB assembly, leading to higher quality products and faster production cycles.

Conclusion

In summary, selecting the appropriate PCB assembly method requires a thorough evaluation of multiple factors, including production volume, component types, and quality standards. By carefully weighing these considerations, you can ensure that the chosen assembly method meets both your technical and business objectives, leading to a successful and efficient product development process.