The Evolution of HDI PCB Technology

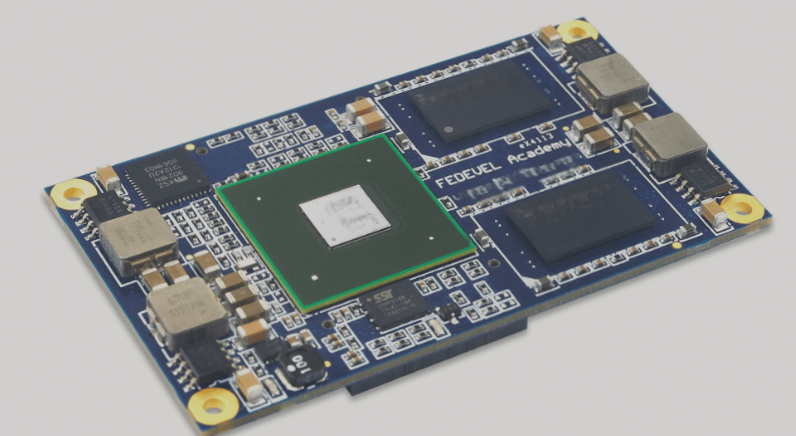

HDI (High Density Interconnect) technology revolutionizes PCB designs, enabling smaller boards with increased trace and component density. By utilizing blind/buried vias and microvias, HDIs create shorter paths between components. In multi-layer HDI PCBs, stacked vias enhance strength and reliability under all conditions.

Enhancing Electronic Functionality

As electronic products become more multifunctional and complex, the demand for reducing distances between integrated circuit components, increasing signal transmission speeds, and managing higher wiring densities grows. HDI circuit board configurations and microvia technology are essential to meet these evolving needs.

The Shift Towards Multilayer Boards

- Single and double-sided panels face wiring challenges, leading to a shift towards multilayer boards.

- Increasing signal line density necessitates additional power and ground planes, making multilayer PCBs more prevalent.

High-Speed Signal Requirements

- Impedance control, AC characteristics, and high-frequency transmission capabilities are crucial for high-speed signals.

- Structures like striplines and microstrips require multilayer configurations to optimize signal integrity.

Advancements in Assembly Methods

- BGA, CSP, DCA, and similar methods have led to high-density PCB domains.

- Microvias under 150μm enhance assembly efficiency and spatial utilization, vital for electronic miniaturization.

Standardizing HDI Terminology

To address the varied naming conventions for HDI boards, the IPC Board Association proposed the term HDI (High Density Interconnection). This generic term simplifies communication and highlights the technology’s high-density connection features.

Global Perspectives on HDI Naming

- European and American companies previously referred to HDI boards as SBU (Sequence Build Up Process).

- Japanese manufacturers termed the technology MVP (Micro Via Process) due to its finer hole structure.

- Some also use the term BUM (Build Up Multilayer Board) to differentiate from traditional MLB (Multilayer Board).

Embracing HDI technology is essential for the future of PCB design, enabling advancements in electronic functionality and miniaturization.