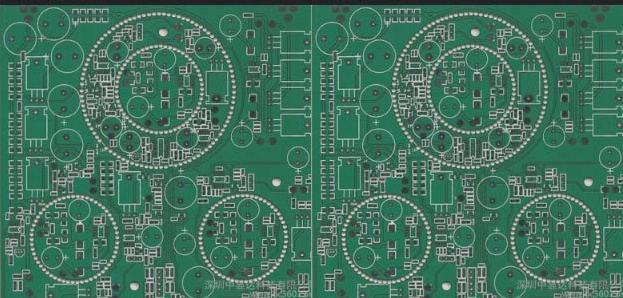

Latest PCB Drilling Techniques and Technologies

As technology advances, PCBs continue to evolve with improved performance and denser circuits. Despite the shrinking size of PCBs, the demand for more components on them is increasing. This poses a challenge for drilling holes on the board, requiring precision and expertise.

Traditional vs. Modern PCB Drilling Methods

- Traditional Method: The conventional approach involves creating inner blind holes by laminating multilayer boards. However, this method is time-consuming, costly, and can impact copper plating.

- Modern Techniques: Various advanced PCB micro-hole technologies are now available, including mechanical drilling, photosensitive drilling, laser drilling, plasma etching, and chemical etching.

Key Modern PCB Drilling Technologies

- Mechanical Drilling: Utilizes high-speed machining with tungsten-cobalt alloy drill bits for smooth hole drilling.

- Laser Drilling: Involves carbon dioxide and ultraviolet laser cutting to burn through copper foil with precision control.

- Plasma Etching: Uses plasma particles to trigger oxidation reactions, ideal for PCBs with resin copper layers.

- Chemical Etching: Involves chemical agents to erode copper foil and resin, facilitating hole creation.

These advanced drilling techniques offer efficient and precise solutions for the evolving demands of modern PCB fabrication, ensuring high-quality and reliable circuit boards for various applications.