—

The PCBA process involves two methods: manual assembly and automated assembly.

In manual assembly, an operator places odd-form components directly onto the circuit board. The soldering process is automated; the operator picks components from bulk bins and places them onto the circuit board moving along the conveyor line. In paste-in-hole assembly, components (surface-mount or through-hole), along with solder paste, may already be on the board, held in place by the tackiness of the paste. Thus, the operator must handle components carefully to avoid displacing them unintentionally.

Special attention must be paid to handling and ESD damage during component placement. Components with snap-in features (e.g., connectors) may require significant force, necessitating careful handling to prevent damage to the board or other components. Tooling is often used to safely press snap-in components onto the circuit board.

For many applications, operators manually solder odd-form components into place after other components have been soldered. During this process, operators must be cautious of ESD damage and prevent thermal damage or unintended solder reflow of neighboring joints. The impact of Pb-free soldering is particularly significant in this scenario. Operators need to ensure that extended soldering times or higher tip temperatures do not cause thermal damage to the component in question or lead to reflow of nearby solder joints.

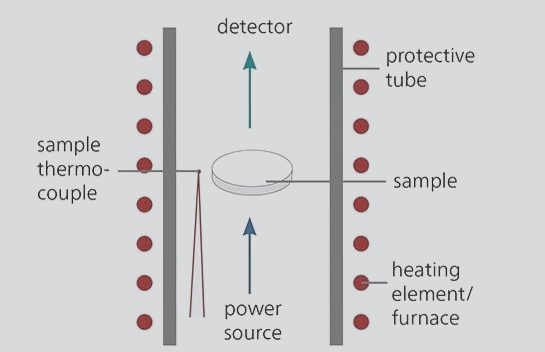

—

This version maintains the structure and meaning of your original text while improving clarity and readability.

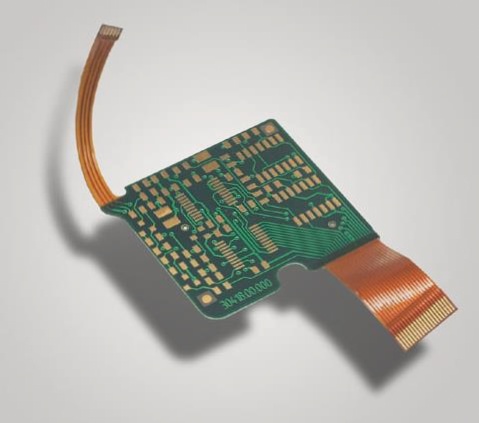

Image 1: Advantages of Mixed Assembly Process in PCBA Processing

It should be noted that whether manual assembly is performed on partially assembled boards to be subsequently soldered or on boards already soldered, these units hold higher value due to prior processing. Therefore, any damage (handling, ESD, thermal, etc.) results in significantly increased yield loss and higher costs for repairing or scrapping damaged boards. Hence, manual assembly steps must be carefully considered during product design and process development activities.

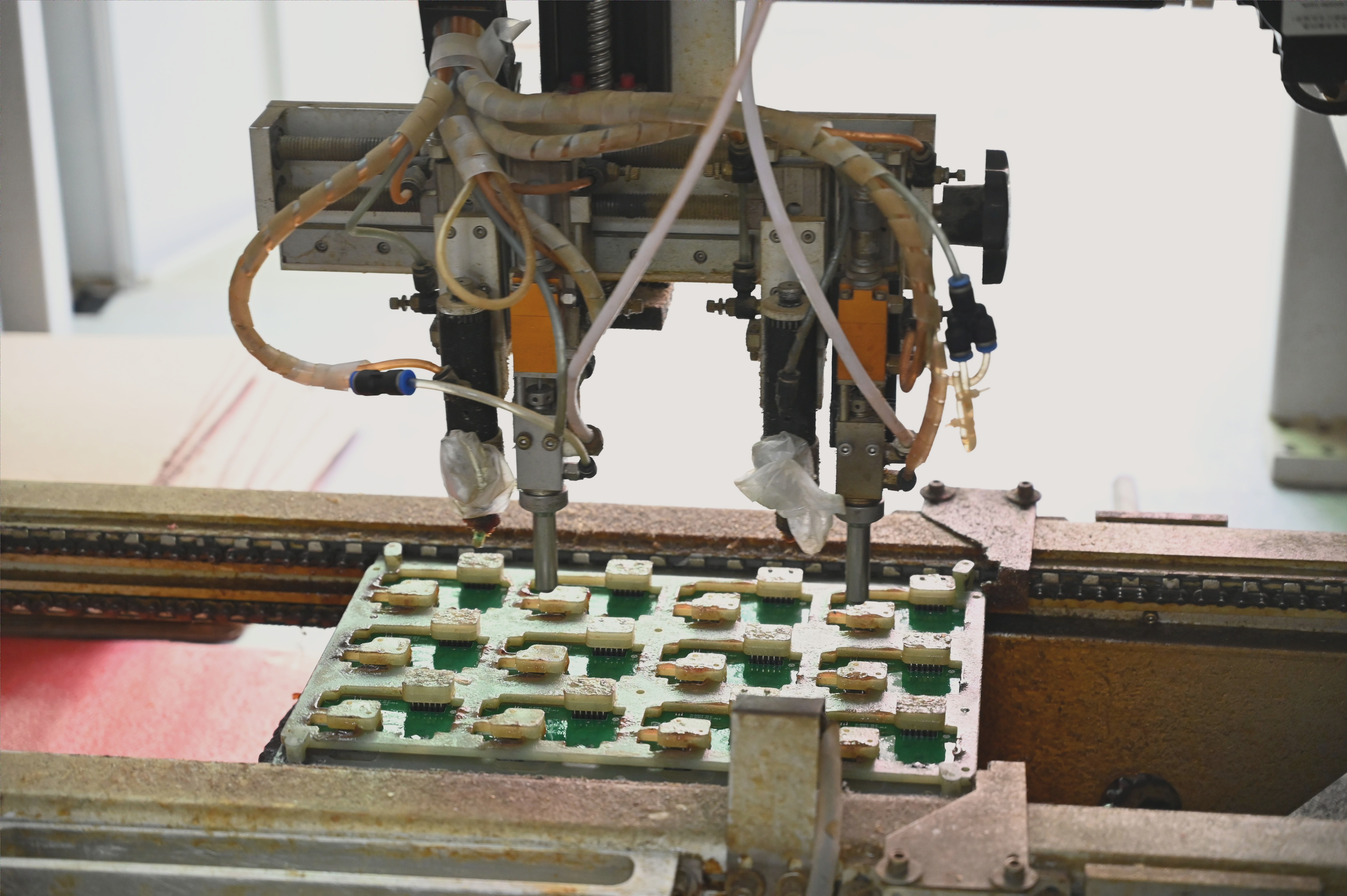

Automated assembly of odd-form components utilizes the same placement equipment as used for standard components, albeit with special tooling or dedicated machines (cells) already set up with necessary tooling and component feeder systems. These machines can be integrated into the assembly process and typically handle multiple types of odd-form components to enhance versatility. For instance, gripper tooling capable of placing various component packages (within design limits) is employed. Once precision and component-type requirements are met, speed becomes the pivotal performance metric for odd-form placement machines. Odd-form component placement typically poses a bottleneck or slows down the production line, thus minimizing the assembly time dedicated to odd-form components accelerates the overall process flow.

Image 2: PCB Automated Assembly

There are both advantages and disadvantages to the automated assembly of odd-form components.

Advantages include:

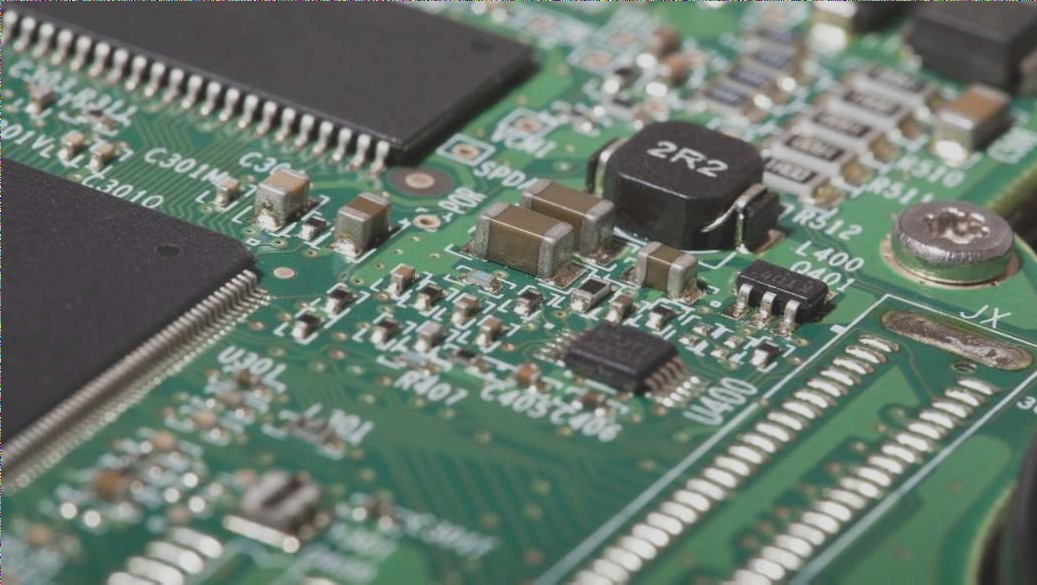

Image 3: Automotive PCB Assembly SERVICE

Disadvantages of automation include: