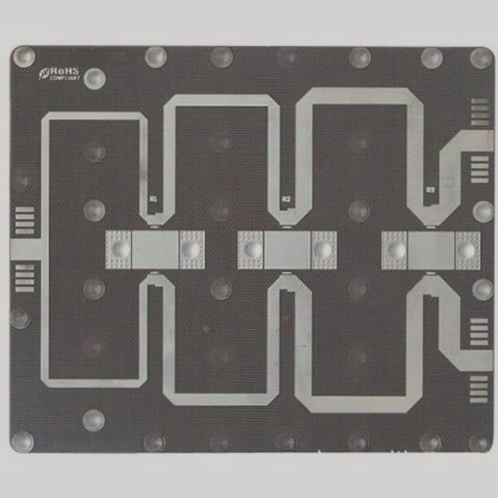

FPC, or flexible printed circuit board, offers numerous advantages over rigid PCBs, including higher wiring and assembly densities, compact size, lightweight construction, thinness, and excellent flexibility. Additionally, FPCs allow for increased wiring layers and design flexibility, and they can incorporate features such as circuit and electromagnetic shielding layers, as well as metal core layers for specialized thermal insulation requirements. These attributes make FPCs highly suitable for applications demanding convenient installation and high reliability.

However, the production of FPCs poses several challenges. Issues such as insufficient termination counts due to cutting tolerance variations, indentations resulting from cutting machine or material inconsistencies, width discrepancies from material slitting processes, and creasing or warping caused by packaging material or tube shaft problems are common. Furthermore, oxidation stemming from improper storage conditions can also render the entire FPC unusable. Therefore, rigorous testing is essential to ensure quality and reliability.

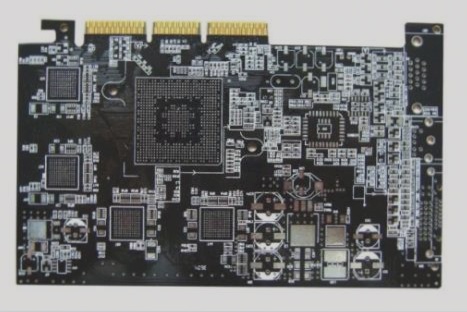

Existing defect detection methods for FPCs are mostly adapted from PCB inspection algorithms. However, due to distinct limitations, FPC defect detection necessitates higher accuracy requirements. The detection templates are larger, and template imaging is prone to deformation. Moreover, FPCs demand meticulous attention to internal circuit wiring accuracy to avoid issues such as line adhesion, crossovers, and short circuits. Additionally, the reflective surface of FPCs complicates detection, as conventional lenses struggle to simultaneously capture internal and external circuitry details, exacerbating detection challenges. Consequently, conventional PCB defect detection methods are unsuitable for FPCs.

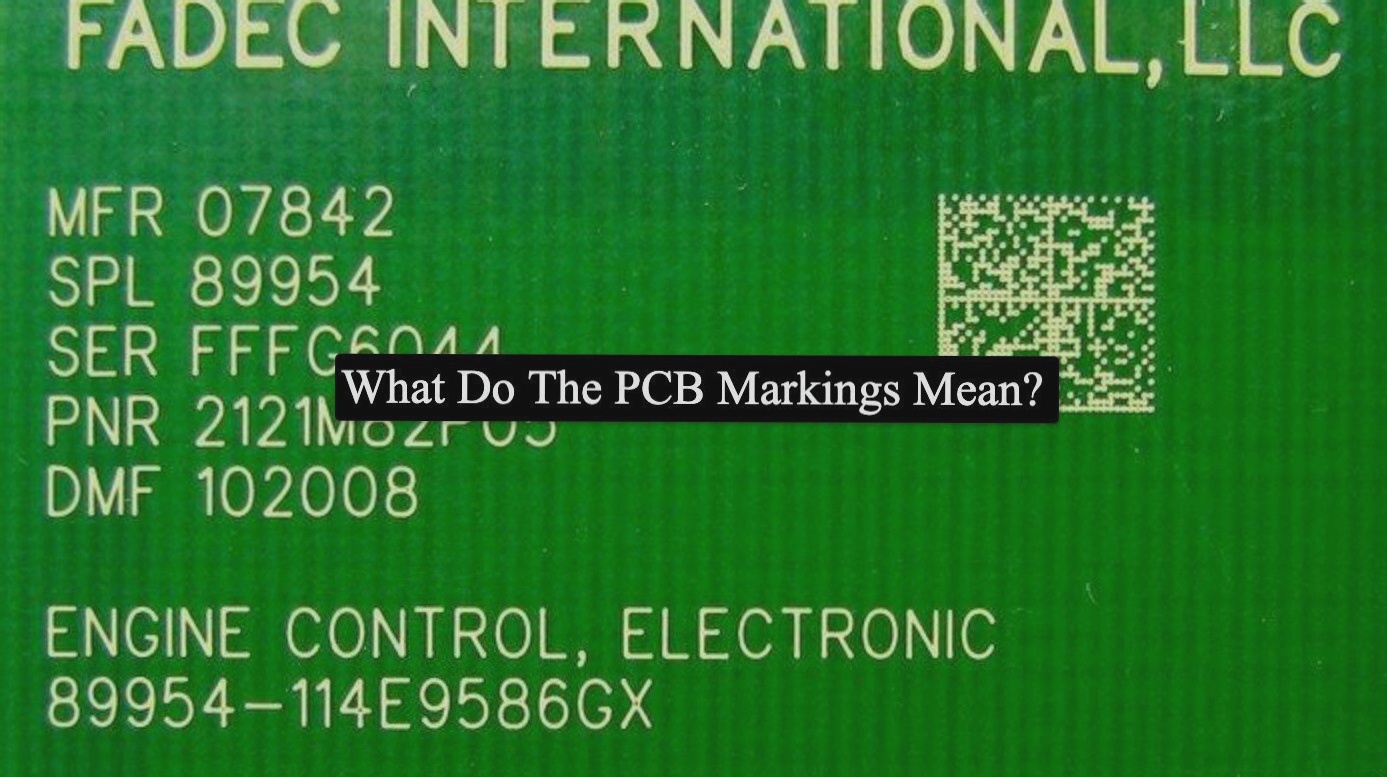

Currently, many companies rely on manual visual inspection to identify FPC defects. However, this approach is costly, inefficient, lacks standardized quality inspection protocols, and is susceptible to oversight and false identifications. Although specialized FPC testing equipment exists, factors such as high equipment costs, limited technical support, and inadequate after-sales services hinder their widespread adoption, particularly in the context of low-cost, high-volume modern production requirements.

However, the production of FPCs poses several challenges. Issues such as insufficient termination counts due to cutting tolerance variations, indentations resulting from cutting machine or material inconsistencies, width discrepancies from material slitting processes, and creasing or warping caused by packaging material or tube shaft problems are common. Furthermore, oxidation stemming from improper storage conditions can also render the entire FPC unusable. Therefore, rigorous testing is essential to ensure quality and reliability.

Existing defect detection methods for FPCs are mostly adapted from PCB inspection algorithms. However, due to distinct limitations, FPC defect detection necessitates higher accuracy requirements. The detection templates are larger, and template imaging is prone to deformation. Moreover, FPCs demand meticulous attention to internal circuit wiring accuracy to avoid issues such as line adhesion, crossovers, and short circuits. Additionally, the reflective surface of FPCs complicates detection, as conventional lenses struggle to simultaneously capture internal and external circuitry details, exacerbating detection challenges. Consequently, conventional PCB defect detection methods are unsuitable for FPCs.

Currently, many companies rely on manual visual inspection to identify FPC defects. However, this approach is costly, inefficient, lacks standardized quality inspection protocols, and is susceptible to oversight and false identifications. Although specialized FPC testing equipment exists, factors such as high equipment costs, limited technical support, and inadequate after-sales services hinder their widespread adoption, particularly in the context of low-cost, high-volume modern production requirements.