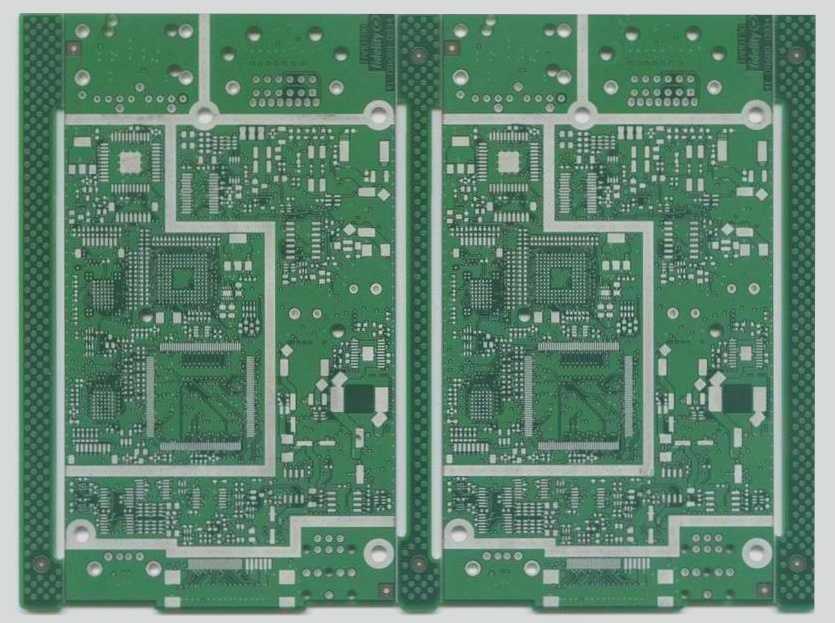

Industrial PCB Materials:

- The selection of PCB materials is a critical aspect of PCB manufacturing.

- Material strength and flexibility directly impact the quality of the PCB.

- Industrial applications require PCB materials with high electrical and heat resistance.

- Heat resistance is crucial to prevent PCB deformation in high-temperature environments.

- Commonly used materials in industrial PCB manufacturing include glass fiber and Teflon.

FR-4 Glass Fiber:

The substrate of industrial PCBs is often made from FR-4 glass fiber material, known for its flame retardant properties and high tensile strength.

- FR-4 materials offer good dimensional stability and excellent insulation properties.

- They provide moisture resistance and a superior flammability index.

- FR-4 is a strong choice for industrial PCB manufacturing due to its reinforcement capabilities.

Teflon:

Teflon, also known as PTFE (polytetrafluoroethylene), is a fluoropolymer with unique characteristics ideal for industrial PCB production.

- PTFE exhibits excellent chemical resistance and electrical insulation properties.

- It offers good heat and low-temperature resistance, making it suitable for industrial settings.

- Teflon has a low coefficient of friction, strong non-stick performance, and good fatigue resistance.

Metal:

Traditional metals like copper, aluminum, and iron play vital roles in industrial PCB manufacturing.

- Copper’s conductivity makes it a top choice for PCBs, aiding in surface mount technology during assembly.

- Aluminum backplanes are commonly used by PCB manufacturers to ensure high quality.

Ceramic Printed Circuit Board:

Ceramics are favored for industrial PCB manufacturing due to their unique properties.

- Ceramic materials offer high hardness, good wear resistance, and excellent electrical insulation.

- They have high resistance to corrosion, high weather resistance, and a high melting point.

- Ceramics are not suitable for all applications due to their higher cost.

Quality and Cost Considerations:

- High-quality materials are essential for durable and long-lasting PCBs in industrial applications.

- Material selection should align with specific application requirements.

- Factors like material quality, component replacement ease, and durability impact the overall cost of industrial PCBs.

Energy and Heat Management:

- Heat capacity and energy conversion rates play crucial roles in determining the reliability of industrial PCBs.

- Understanding how materials handle power conversion into temperature is key for optimal PCB performance.