**PCB Commonly Used Terminals**

1. Currently, the country has increasing demands for environmental protection and intensified efforts in regulatory compliance. This presents both challenges and opportunities for PCB manufacturers. If PCB factories commit to addressing environmental pollution, FPC flexible circuit board products can take a leading position in the market, offering PCB manufacturers opportunities for further growth.

2. The Internet era has transformed the traditional marketing landscape, consolidating numerous resources through online platforms. This shift has accelerated the development of FPC flexible circuit boards. However, as development speeds up, PCB factories will increasingly encounter environmental challenges. Nevertheless, advancements in the Internet have also propelled significant progress in environmental protection and environmental data management. Environmental information centers and green electronic procurement are gradually being integrated into production and operational practices. From this perspective, the environmental issues faced by PCB factories can be addressed through two main approaches.

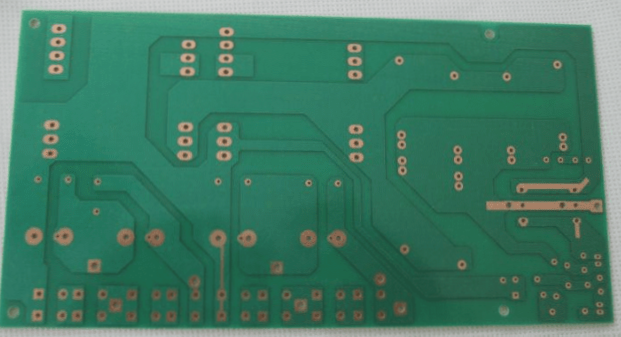

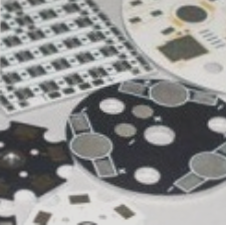

3. Classification can be based on either material or design. When categorized by material, copper terminals are prevalent. In terms of design, PCB terminals can be divided into plug-in terminal blocks, direct soldering terminal blocks, and spring terminals, with plug-in and spring-type terminals being the most common.

1. The spring-type terminal is an innovative terminal that employs spring-loaded mechanisms. It has gained widespread use across the global electrical and electronic engineering sectors, including lighting, elevator control, instrumentation, power supply, chemical, and automotive applications.

2. All metal components of the spring-type terminal blocks incorporate spring mechanisms, while the plastic casing is constructed from PA66 insulating material. These spring-loaded terminal blocks are user-friendly, maintenance-free, and feature an airtight contact device system, making them durable, reliable, and cost-effective.

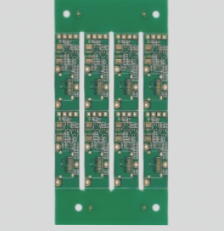

3. The PTB plug-in series terminal block consists of two components: one part tightly secures the wire, which then plugs into the second part that is soldered to the PCB board. The mechanical design of this connection, along with its anti-vibration features, ensures a long-lasting airtight connection and the reliability of the finished product.

4. Mounting ears can be added to both ends of the socket to provide substantial protection for the tabs and prevent misalignment. Additionally, this socket design guarantees proper insertion into the parent body. The socket may also include assembly and locking buckles. The assembly buckle provides a firmer attachment to the PCB, while the locking buckle secures the connection between the socket and the parent body after installation.

5. A variety of socket designs can accommodate different insertion orientations, such as horizontal, vertical, or inclined, depending on customer preferences. Both metric and standard wire gauges are available, with no minimum order requirements—clients can purchase as few as one PCB from us. We prioritize your needs and won’t push you to buy unnecessary items, allowing you to save money.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me