Comparing Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) for 3D Printing Nylon

Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) are popular 3D printing methods for black and white nylon, respectively. Both fall under powder bed-based 3D printing, where layers of powder are fused together. The key difference lies in their heat sources: SLS uses a laser, while MJF uses an ink that absorbs infrared light.

Differences in Nylon Properties

Process

- SLS: Powder is sintered by a laser in layers, requiring cooling before part removal.

- MJF: Inkjet sprays fusing agent, with infrared heat for sintering, also needing cooling.

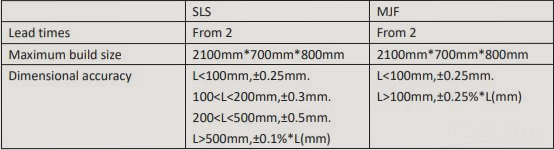

Dimensional Accuracy

Both methods offer high accuracy, but MJF excels due to its higher DPI and detailing agent for fine details.

Appearance and Surface Quality

- MJF parts are light grey due to black fusing agent, while SLS parts are white and can be dyed.

- Both have granular textures but can be smoothed post-processing.

Material Properties

PA 12 (nylon) is common; MJF parts are stronger and more consistent across axes than SLS parts.

Cost and Delivery Time

Black nylon has superior performance but comes at a higher cost. Delivery times are similar, with black nylon potentially faster due to better powder recovery.

Tolerances for SLS and MJF at WellCircuits

If you have inquiries about PCB and PCBA, reach out to us at info@wellcircuits.com.