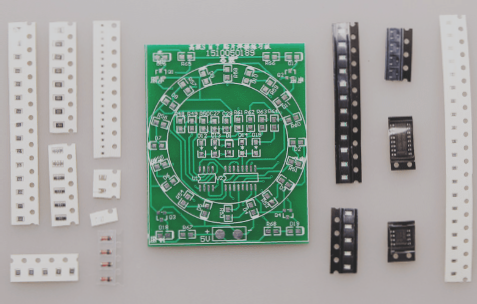

Ceramic Substrates in PCBs

- Ceramic substrates are essential for providing electrical connections and insulation between electronic components.

- Optimization is key, with ceramic substrates, resin substrates, and metal matrix materials being popular choices.

- Ceramic substrates excel in electrical insulation, chemical stability, and thermal conductivity.

- Beryllium oxide, alumina, and aluminum nitride are common ceramic substrate materials.

Beryllium Oxide (BeO) Ceramic Substrate

Beryllium oxide ceramic substrates offer exceptional thermal conductivity but pose health risks due to toxic powder.

Aluminum Nitride (AlN) Ceramic Substrate

Aluminum nitride ceramics provide high thermal conductivity and mechanical strength but come with higher production costs compared to alumina substrates.

Alumina (Al2O3) Ceramic Substrate

Alumina ceramics are cost-effective with low dielectric loss and good chemical stability.

PCB Iron Substrates

- PCB iron substrates are widely used for their thermal conductivity, electrical insulation, and mechanical processing advantages.

- They consist of circuit layers, insulating layers, and metal base layers, making them suitable for high-power devices.

Heat Dissipation in PCB Iron Substrates

PCB iron substrates effectively dissipate heat in high-density boards, addressing thermal issues present in conventional substrates like FR4 and CEM3.

Dimensional Stability of PCB Iron Substrates

Aluminum-based printed boards exhibit superior dimensional stability under varying temperatures, ensuring reliability in electronic devices.

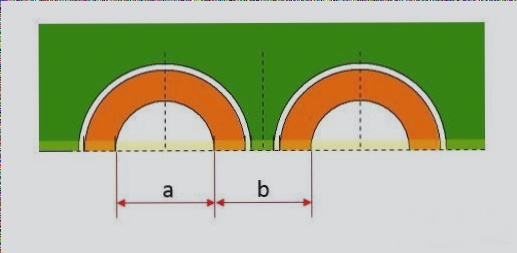

Thermal Expansion in PCB Iron Substrates

Aluminum-based PCBs manage thermal expansion, enhancing durability and reliability in machines and electronic devices, especially in Surface Mount Technology (SMT) applications.

Advantages of PCB Iron Substrates

- Enhanced shielding capability

- Replacement for fragile ceramic substrates

- Compatible with surface mounting technology

- Reduction of printed board area

- Substitute for radiators and other components

These features contribute to improved product heat resistance and physical properties. Additionally, the use of PCB iron substrates can lead to cost savings and reduced labor needs.